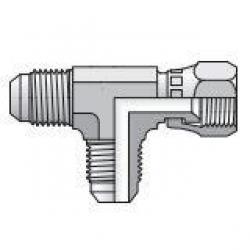

37deg Flare JIC x JIC Swivel x 37deg Flare JIC

1-1/2in

View:

Active Filters :

Part #:203960

- Straight Adaptors -22 CTS x MNPT ONE END MALE NATIONAL PIPE THREAD

A.Y. McDonald Service Fittings are manufactured to meet or exceed the AWWA C800 (latest revision) standard. Our service fittings arerated to withstand the same pressures as the tubing they are designed to fit. They are designed and tested for cold potable water only.EPDM rubber gaskets are used in our Compression fittings.

Qty:

Part #:706624

- Inverted Bucket Steam TrapsEnergy efficient because it's so reliable The inverted bucket is the most reliable steam trap operating principle known. The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure. Since the bucket is open at the bottom, it resists damage from water hammer, and wear points are heavily reinforced for long life. The inverted bucket has only two moving parts-the valve lever assembly and the bucket. That means no fixed points, no complicated linkage. Nothing to stick, bind or clog. Conserves energy even in the presence of wear Armstrong inverted bucket steam traps open and close based on the difference in density between condensate and steam-the inverted bucket principle. They open and close gently, minimizing wear. This simple fact means that inverted buckets are subject to less wear than some other types of traps. In fact, as an Armstrong inverted bucket trap wears, its tight seal actually improves. The valve and seat of the Armstrong trap provide essentially line contact-resulting in a tight seal because the entire closing force is concentrated on one narrow seating ring. An Armstrong inverted bucket steam trap continues to operate efficiently with use. Gradual wear slightly increases the diameter of the seat and alters the shape and diameter of the valve. But, as this occurs, a tight seal is still preserved-the ball merely seats itself more deeply. Corrosion-resistant parts The stainless steel valve and seat of the Armstrong inverted bucket steam trap are individually ground and lapped together in matched sets. All other working parts are wear- and corrosion-resistant stainless steel. Venting of air and CO2 The Armstrong inverted bucket provides continuous automatic air and CO2 venting with no cooling lag or threat of air binding. Operation against back pressure The Armstrong inverted bucket has excellent performance against back pressure. It has no adverse effect on inverted bucket operation other than to reduce its capacity by the low differential. The bucket simply requires less force to pull the valve open and cycle the trap. Freedom from dirt problems Armstrong designed its inverted bucket to be virtually free of dirt problems. The valve and seat are at the top of the trap, far away from the larger particles of dirt, which fall to the bottom. Here, the up-and-down action of the bucket pulverizes them. Since the valve of an inverted bucket is either fully closed or open, dirt particles pass freely. And the swift flow of condensate from under the bucket's edge creates a unique self-scrubbing action that sweeps dirt out of the trap.

Qty:

closeout

$3.70 MSRP

$

1.21

Qty:

Part #:206954

- Straight Ball Valves - Female National Pipe Thread (FNPT) x Female National Pipe Thread (FNPT)

90º ON/OFF TEE OPERATING HEAD FNPT x FNPT

A.Y. McDonald Ball Curb Stops maintain a low turning torque and bubble-tight 300 PSIG water pressure rating due to the PTFE coated brassball that is supported by two blow-out proof EPDM seals. The end piece joint is sealed with an EPDM O-ring and thread locker. McDonaldBall Curb Stops offer positive shut-off from either direction and are available with a wide variety of end connections.

$

438.59

Qty:

Part #:206857

- Straight Ball Valves - Compression 90º DEGREE ON/OFF TEE OPERATING HEAD -22 CTS x -22 CTS

A.Y. McDonald Ball Curb Stops maintain a low turning torque and bubble-tight 300 PSIG water pressure rating due to the PTFE coated brassball that is supported by two blow-out proof EPDM seals. The end piece joint is sealed with an EPDM O-ring and thread locker. McDonaldBall Curb Stops offer positive shut-off from either direction and are available with a wide variety of end connections.

$

638.00

Qty:

Part #:204023

- Plug Style - AWWA Inlets AWWA x -22 CTS

A.Y. McDonald Plug Style Corporation Stops come standard with a 360º operating head. The one piece body and plug are precisionmachined to assure a perfect match between the plug and the body to allow operating pressures of 100 PSI on 1/2&rdquo, 3/4&rdquo and 1&rdquo valvesand 80 PSI on 1 1/4&rdquo, 1 1/2&rdquo and 2&rdquo valves. This same machining precision carries over to the threads to assure A.Y. McDonald&rsquos highquality and compatibility with direct taps and saddle applications.

$

620.13

Qty:

Part #:203895

- Straight Adaptors ONE END FEMALE NATIONAL PIPE THREAD Flare x FNPT

A.Y. McDonald Service Fittings are manufactured to meet or exceed the AWWA C800 (latest revision) standard. Our service fittings arerated to withstand the same pressures as the tubing they are designed to fit. They are designed and tested for cold potable water only.EPDM rubber gaskets are used in our Compression fittings.

Qty:

Part #:203947

- Straight Couplings SAME CONNECTIONS ON BOTH ENDS - NO INTERNAL PIPE STOP ON STRAIGHT SIZES -22 CTS x -22 CTS

A.Y. McDonald Service Fittings are manufactured to meet or exceed the AWWA C800 (latest revision) standard. Our service fittings arerated to withstand the same pressures as the tubing they are designed to fit. They are designed and tested for cold potable water only.EPDM rubber gaskets are used in our Compression fittings.

Qty:

Part #:203887

- Straight Adaptors ONE END FEMALE NATIONAL PIPE THREAD -22 CTS x FNPT

A.Y. McDonald Service Fittings are manufactured to meet or exceed the AWWA C800 (latest revision) standard. Our service fittings arerated to withstand the same pressures as the tubing they are designed to fit. They are designed and tested for cold potable water only.EPDM rubber gaskets are used in our Compression fittings.

Qty:

Qty:

Qty:

Part #:501-C5324-1

- Inverted Bucket Steam TrapsEnergy efficient because it's so reliable The inverted bucket is the most reliable steam trap operating principle known. The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure. Since the bucket is open at the bottom, it resists damage from water hammer, and wear points are heavily reinforced for long life. The inverted bucket has only two moving parts-the valve lever assembly and the bucket. That means no fixed points, no complicated linkage. Nothing to stick, bind or clog. Conserves energy even in the presence of wear Armstrong inverted bucket steam traps open and close based on the difference in density between condensate and steam-the inverted bucket principle. They open and close gently, minimizing wear. This simple fact means that inverted buckets are subject to less wear than some other types of traps. In fact, as an Armstrong inverted bucket trap wears, its tight seal actually improves. The valve and seat of the Armstrong trap provide essentially line contact-resulting in a tight seal because the entire closing force is concentrated on one narrow seating ring. An Armstrong inverted bucket steam trap continues to operate efficiently with use. Gradual wear slightly increases the diameter of the seat and alters the shape and diameter of the valve. But, as this occurs, a tight seal is still preserved-the ball merely seats itself more deeply. Corrosion-resistant parts The stainless steel valve and seat of the Armstrong inverted bucket steam trap are individually ground and lapped together in matched sets. All other working parts are wear- and corrosion-resistant stainless steel. Venting of air and CO2 The Armstrong inverted bucket provides continuous automatic air and CO2 venting with no cooling lag or threat of air binding. Operation against back pressure The Armstrong inverted bucket has excellent performance against back pressure. It has no adverse effect on inverted bucket operation other than to reduce its capacity by the low differential. The bucket simply requires less force to pull the valve open and cycle the trap. Freedom from dirt problems Armstrong designed its inverted bucket to be virtually free of dirt problems. The valve and seat are at the top of the trap, far away from the larger particles of dirt, which fall to the bottom. Here, the up-and-down action of the bucket pulverizes them. Since the valve of an inverted bucket is either fully closed or open, dirt particles pass freely. And the swift flow of condensate from under the bucket's edge creates a unique self-scrubbing action that sweeps dirt out of the trap.

Qty:

Armstrong 2011 1/8in Orifice 125lb Stainless Steel Inverted Bucket Trap, Two Bolt Connection C5324-4

- Inverted Bucket Steam TrapsEnergy efficient because it's so reliable

The inverted bucket is the most reliable steam trap operating principle known. The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure.

Since the bucket is open at the bottom, it resists damage from water hammer, and wear points are heavily reinforced for long life. The inverted bucket has only two moving parts-the valve lever assembly and the bucket. That means no fixed points, no complicated linkage. Nothing to stick, bind or clog.

Conserves energy even in the presence of wear

Armstrong inverted bucket steam traps open and close based on the difference in density between condensate and steam-the inverted bucket principle. They open and close gently, minimizing wear. This simple fact means that inverted buckets are subject to less wear than some other types of traps.

In fact, as an Armstrong inverted bucket trap wears, its tight seal actually improves. The valve and seat of the Armstrong trap provide essentially line contact-resulting in a tight seal because the entire closing force is concentrated on one narrow seating ring.

An Armstrong inverted bucket steam trap continues to operate efficiently with use. Gradual wear slightly increases the diameter of the seat and alters the shape and diameter of the valve. But, as this occurs, a tight seal is still preserved-the ball merely seats itself more deeply.

Corrosion-resistant parts

The stainless steel valve and seat of the Armstrong inverted bucket steam trap are individually ground and lapped together in matched sets. All other working parts are wear- and corrosion-resistant stainless steel.

Venting of air and CO2

The Armstrong inverted bucket provides continuous automatic air and CO2 venting with no cooling lag or threat of air binding.

Operation against back pressure

The Armstrong inverted bucket has excellent performance against back pressure. It has no adverse effect on inverted bucket operation other than to reduce its capacity by the low differential. The bucket simply requires less force to pull the valve open and cycle the trap.

Freedom from dirt problems

Armstrong designed its inverted bucket to be virtually free of dirt problems. The valve and seat are at the top of the trap, far away from the larger particles of dirt, which fall to the bottom. Here, the up-and-down action of the bucket pulverizes them.

Since the valve of an inverted bucket is either fully closed or open, dirt particles pass freely. And the swift flow of condensate from under the bucket's edge creates a unique self-scrubbing action that sweeps dirt out of the trap.

Qty:

Armstrong 2011 5/32in Orifice 70lb Stainless Steel Inverted Bucket Trap, Two Bolt Connection C5324-5

- Inverted Bucket Steam TrapsEnergy efficient because it's so reliable

The inverted bucket is the most reliable steam trap operating principle known. The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure.

Since the bucket is open at the bottom, it resists damage from water hammer, and wear points are heavily reinforced for long life. The inverted bucket has only two moving parts-the valve lever assembly and the bucket. That means no fixed points, no complicated linkage. Nothing to stick, bind or clog.

Conserves energy even in the presence of wear

Armstrong inverted bucket steam traps open and close based on the difference in density between condensate and steam-the inverted bucket principle. They open and close gently, minimizing wear. This simple fact means that inverted buckets are subject to less wear than some other types of traps.

In fact, as an Armstrong inverted bucket trap wears, its tight seal actually improves. The valve and seat of the Armstrong trap provide essentially line contact-resulting in a tight seal because the entire closing force is concentrated on one narrow seating ring.

An Armstrong inverted bucket steam trap continues to operate efficiently with use. Gradual wear slightly increases the diameter of the seat and alters the shape and diameter of the valve. But, as this occurs, a tight seal is still preserved-the ball merely seats itself more deeply.

Corrosion-resistant parts

The stainless steel valve and seat of the Armstrong inverted bucket steam trap are individually ground and lapped together in matched sets. All other working parts are wear- and corrosion-resistant stainless steel.

Venting of air and CO2

The Armstrong inverted bucket provides continuous automatic air and CO2 venting with no cooling lag or threat of air binding.

Operation against back pressure

The Armstrong inverted bucket has excellent performance against back pressure. It has no adverse effect on inverted bucket operation other than to reduce its capacity by the low differential. The bucket simply requires less force to pull the valve open and cycle the trap.

Freedom from dirt problems

Armstrong designed its inverted bucket to be virtually free of dirt problems. The valve and seat are at the top of the trap, far away from the larger particles of dirt, which fall to the bottom. Here, the up-and-down action of the bucket pulverizes them.

Since the valve of an inverted bucket is either fully closed or open, dirt particles pass freely. And the swift flow of condensate from under the bucket's edge creates a unique self-scrubbing action that sweeps dirt out of the trap.

Qty:

Part #:501-C5324-6

- Inverted Bucket Steam TrapsEnergy efficient because it's so reliable

The inverted bucket is the most reliable steam trap operating principle known. The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure.

Since the bucket is open at the bottom, it resists damage from water hammer, and wear points are heavily reinforced for long life. The inverted bucket has only two moving parts-the valve lever assembly and the bucket. That means no fixed points, no complicated linkage. Nothing to stick, bind or clog.

Conserves energy even in the presence of wear

Armstrong inverted bucket steam traps open and close based on the difference in density between condensate and steam-the inverted bucket principle. They open and close gently, minimizing wear. This simple fact means that inverted buckets are subject to less wear than some other types of traps.

In fact, as an Armstrong inverted bucket trap wears, its tight seal actually improves. The valve and seat of the Armstrong trap provide essentially line contact-resulting in a tight seal because the entire closing force is concentrated on one narrow seating ring.

An Armstrong inverted bucket steam trap continues to operate efficiently with use. Gradual wear slightly increases the diameter of the seat and alters the shape and diameter of the valve. But, as this occurs, a tight seal is still preserved-the ball merely seats itself more deeply.

Corrosion-resistant parts

The stainless steel valve and seat of the Armstrong inverted bucket steam trap are individually ground and lapped together in matched sets. All other working parts are wear- and corrosion-resistant stainless steel.

Venting of air and CO2

The Armstrong inverted bucket provides continuous automatic air and CO2 venting with no cooling lag or threat of air binding.

Operation against back pressure

The Armstrong inverted bucket has excellent performance against back pressure. It has no adverse effect on inverted bucket operation other than to reduce its capacity by the low differential. The bucket simply requires less force to pull the valve open and cycle the trap.

Freedom from dirt problems

Armstrong designed its inverted bucket to be virtually free of dirt problems. The valve and seat are at the top of the trap, far away from the larger particles of dirt, which fall to the bottom. Here, the up-and-down action of the bucket pulverizes them.

Since the valve of an inverted bucket is either fully closed or open, dirt particles pass freely. And the swift flow of condensate from under the bucket's edge creates a unique self-scrubbing action that sweeps dirt out of the trap.

Qty:

Part #:501-C5324-7

- Inverted Bucket Steam TrapsEnergy efficient because it's so reliable The inverted bucket is the most reliable steam trap operating principle known. The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure. Since the bucket is open at the bottom, it resists damage from water hammer, and wear points are heavily reinforced for long life. The inverted bucket has only two moving parts-the valve lever assembly and the bucket. That means no fixed points, no complicated linkage. Nothing to stick, bind or clog. Conserves energy even in the presence of wear Armstrong inverted bucket steam traps open and close based on the difference in density between condensate and steam-the inverted bucket principle. They open and close gently, minimizing wear. This simple fact means that inverted buckets are subject to less wear than some other types of traps. In fact, as an Armstrong inverted bucket trap wears, its tight seal actually improves. The valve and seat of the Armstrong trap provide essentially line contact-resulting in a tight seal because the entire closing force is concentrated on one narrow seating ring. An Armstrong inverted bucket steam trap continues to operate efficiently with use. Gradual wear slightly increases the diameter of the seat and alters the shape and diameter of the valve. But, as this occurs, a tight seal is still preserved-the ball merely seats itself more deeply. Corrosion-resistant parts The stainless steel valve and seat of the Armstrong inverted bucket steam trap are individually ground and lapped together in matched sets. All other working parts are wear- and corrosion-resistant stainless steel. Venting of air and CO2 The Armstrong inverted bucket provides continuous automatic air and CO2 venting with no cooling lag or threat of air binding. Operation against back pressure The Armstrong inverted bucket has excellent performance against back pressure. It has no adverse effect on inverted bucket operation other than to reduce its capacity by the low differential. The bucket simply requires less force to pull the valve open and cycle the trap. Freedom from dirt problems Armstrong designed its inverted bucket to be virtually free of dirt problems. The valve and seat are at the top of the trap, far away from the larger particles of dirt, which fall to the bottom. Here, the up-and-down action of the bucket pulverizes them. Since the valve of an inverted bucket is either fully closed or open, dirt particles pass freely. And the swift flow of condensate from under the bucket's edge creates a unique self-scrubbing action that sweeps dirt out of the trap.

Qty:

Part #:501-D515565

- Bimetallic Superheat Steam TrapsBimetallic steam traps have the ability to handle large start-up loads. As the system increases in temperature and pressure, the traps stacked nickel-chrome bimetallic elements start to expand, allowing for tight shutoff as steam reaches the trap, thus preventing steam loss.

The bimetallic trap offers resistance to water hammer. A titanium valve and seat on high-pressure bimetallic traps ensure extremely long service life in the harsh environment of superheated steam systems.

Qty:

Part #:501-D515622

- Bimetallic Superheat Steam TrapsBimetallic steam traps have the ability to handle large start-up loads. As the system increases in temperature and pressure, the traps stacked nickel-chrome bimetallic elements start to expand, allowing for tight shutoff as steam reaches the trap, thus preventing steam loss.

The bimetallic trap offers resistance to water hammer. A titanium valve and seat on high-pressure bimetallic traps ensure extremely long service life in the harsh environment of superheated steam systems.

Qty:

Part #:501-D517239

- Bimetallic Superheat Steam TrapsBimetallic steam traps have the ability to handle large start-up loads. As the system increases in temperature and pressure, the traps stacked nickel-chrome bimetallic elements start to expand, allowing for tight shutoff as steam reaches the trap, thus preventing steam loss.

The bimetallic trap offers resistance to water hammer. A titanium valve and seat on high-pressure bimetallic traps ensure extremely long service life in the harsh environment of superheated steam systems.

Qty:

Part #:1128-6 R6X-S

- Performance Characteristics

Connection Type

37° Flare

Industry Standards

SAE J514

Maximum Dynamic Pressure (psi)

6000

Shape

Tee

Connection Style

Run Tee

Connection 1 Style

Male 37° Flare

Connection 1 Tube O.D. (inch)

3/8

Connection 1 Tube O.D. (mm)

10

Connection 2 Style

Female 37° Flare Swivel

Connection 2 Tube O.D. (inch)

3/8

Connection 2 Tube O.D. (mm)

10

Connection 2 Thread Size (inch)

na

Connection 2 Thread Size (mm)

na

Connection 3 Style

Male 37° Flare

Connection 3 Tube O.D. (inch)

3/8

Connection 3 Tube O.D. (mm)

10

Connection 3 Thread Size (inch)

na

Connection 3 Thread Size (mm)

na

Connection 4 Style

na

Connection 4 Tube O.D. (inch)

na

Connection 4 Tube O.D. (mm)

na

O-Ring Material

na

Body Material

Steel, Chromium-6 Free

$

9.21

Qty:

Part #:1128-12 R6X-S

- Performance Characteristics

Connection Type

37° Flare

Industry Standards

SAE J514

Maximum Dynamic Pressure (psi)

5000

Shape

Tee

Connection Style

Run Tee

Connection 1 Style

Male 37° Flare

Connection 1 Tube O.D. (inch)

3/4

Connection 1 Tube O.D. (mm)

18, 20

Connection 2 Style

Female 37° Flare Swivel

Connection 2 Tube O.D. (inch)

3/4

Connection 2 Tube O.D. (mm)

18, 20

Connection 2 Thread Size (inch)

na

Connection 2 Thread Size (mm)

na

Connection 3 Style

Male 37° Flare

Connection 3 Tube O.D. (inch)

3/4

Connection 3 Tube O.D. (mm)

18, 20

Connection 3 Thread Size (inch)

na

Connection 3 Thread Size (mm)

na

Connection 4 Style

na

Connection 4 Tube O.D. (inch)

na

Connection 4 Tube O.D. (mm)

na

O-Ring Material

na

Body Material

Steel, Chromium-6 Free

$

16.23

Qty:

Part #:709861

- CD-3300 Series Disc Steam TrapsAll stainless with 360° connector For pressures to 450 psig (31 barg) Capacities to 800 lb/hr (363 kg/hr) The Armstrong CD-3300 is a three-discharge port design, which provides stable disc operation to extend operating life. The CD-3300 is piped in-line by a 360° universal connector, which allows you to install the trap in virtually any piping configuration. Armstrong&rsquos unique standard connector or our IS-2 connector with integral strainer makes the CD-3300 easy to install, easy to renew. You save on labor time and cost because the connector simplifies piping and remains in-line.

Qty:

Part #:1128-8 R6X-S

- Performance Characteristics

Connection Type

37° Flare

Industry Standards

SAE J514

Maximum Dynamic Pressure (psi)

6000

Shape

Tee

Connection Style

Run Tee

Connection 1 Style

Male 37° Flare

Connection 1 Tube O.D. (inch)

1/2

Connection 1 Tube O.D. (mm)

12

Connection 2 Style

Female 37° Flare Swivel

Connection 2 Tube O.D. (inch)

1/2

Connection 2 Tube O.D. (mm)

12

Connection 2 Thread Size (inch)

na

Connection 2 Thread Size (mm)

na

Connection 3 Style

Male 37° Flare

Connection 3 Tube O.D. (inch)

1/2

Connection 3 Tube O.D. (mm)

12

Connection 3 Thread Size (inch)

na

Connection 3 Thread Size (mm)

na

Connection 4 Style

na

Connection 4 Tube O.D. (inch)

na

Connection 4 Tube O.D. (mm)

na

O-Ring Material

na

Body Material

Steel, Chromium-6 Free

Qty:

$

546.01

Qty:

Displaying: 1 - 24 of 24 Matching Items