Carbon Steel

Armstrong International

View:

Active Filters :

- Brand: Armstrong International

- Material: Carbon Steel

- Maximum Operating Pressure (psi): 150psi

Part #:501-D30854

- DS Series In-Line Condensate SeparatorsCarbon Steel Drain SeparatorCondensate in steam and air piping reduces thermal efficiency, causes water hammer, corrodes equipment such as valves and pipes, and causes other problems.

In-line (drain) separators DS-1, DS-2, DS-3, and DS-4 separate condensate efficiently by using the centrifugal force of steam or air created by introducing it into a specifically shaped path. Because of the simple structure of the drain separators, pressure loss is minimized, enabling clean, dry steam or air to be fed to equipment.

When steam or air flow enters the drain separator, centrifugal force is generated in the fluid because of the devices internal structural design. The fluid drains along the wall because of the difference in specific gravity with steam or air, eventually striking the baffle. The baffle guides the fluid to the drain outlet and to the trap, which drains it. As a result, small dirt particles and condensate are separated and removed from the system through the bottom drain.

• Cyclone structure maximizes liquid separation efficiency

• Pressure loss is extremely low

• No moving parts means no breakdowns

Qty:

Part #:501-D33858

- DS Series In-Line Condensate SeparatorsCarbon Steel Drain SeparatorCondensate in steam and air piping reduces thermal efficiency, causes water hammer, corrodes equipment such as valves and pipes, and causes other problems.

In-line (drain) separators DS-1, DS-2, DS-3, and DS-4 separate condensate efficiently by using the centrifugal force of steam or air created by introducing it into a specifically shaped path. Because of the simple structure of the drain separators, pressure loss is minimized, enabling clean, dry steam or air to be fed to equipment.

When steam or air flow enters the drain separator, centrifugal force is generated in the fluid because of the devices internal structural design. The fluid drains along the wall because of the difference in specific gravity with steam or air, eventually striking the baffle. The baffle guides the fluid to the drain outlet and to the trap, which drains it. As a result, small dirt particles and condensate are separated and removed from the system through the bottom drain.

• Cyclone structure maximizes liquid separation efficiency

• Pressure loss is extremely low

• No moving parts means no breakdowns

Qty:

Part #:501-D33860

- DS Series In-Line Condensate SeparatorsCarbon Steel Drain SeparatorCondensate in steam and air piping reduces thermal efficiency, causes water hammer, corrodes equipment such as valves and pipes, and causes other problems.

In-line (drain) separators DS-1, DS-2, DS-3, and DS-4 separate condensate efficiently by using the centrifugal force of steam or air created by introducing it into a specifically shaped path. Because of the simple structure of the drain separators, pressure loss is minimized, enabling clean, dry steam or air to be fed to equipment.

When steam or air flow enters the drain separator, centrifugal force is generated in the fluid because of the devices internal structural design. The fluid drains along the wall because of the difference in specific gravity with steam or air, eventually striking the baffle. The baffle guides the fluid to the drain outlet and to the trap, which drains it. As a result, small dirt particles and condensate are separated and removed from the system through the bottom drain.

• Cyclone structure maximizes liquid separation efficiency

• Pressure loss is extremely low

• No moving parts means no breakdowns

Qty:

Part #:501-D33863

- DS Series In-Line Condensate SeparatorsCarbon Steel Drain SeparatorCondensate in steam and air piping reduces thermal efficiency, causes water hammer, corrodes equipment such as valves and pipes, and causes other problems.

In-line (drain) separators DS-1, DS-2, DS-3, and DS-4 separate condensate efficiently by using the centrifugal force of steam or air created by introducing it into a specifically shaped path. Because of the simple structure of the drain separators, pressure loss is minimized, enabling clean, dry steam or air to be fed to equipment.

When steam or air flow enters the drain separator, centrifugal force is generated in the fluid because of the devices internal structural design. The fluid drains along the wall because of the difference in specific gravity with steam or air, eventually striking the baffle. The baffle guides the fluid to the drain outlet and to the trap, which drains it. As a result, small dirt particles and condensate are separated and removed from the system through the bottom drain.

• Cyclone structure maximizes liquid separation efficiency

• Pressure loss is extremely low

• No moving parts means no breakdowns

Qty:

Part #:501-D33865

- DS Series In-Line Condensate SeparatorsCarbon Steel Drain SeparatorCondensate in steam and air piping reduces thermal efficiency, causes water hammer, corrodes equipment such as valves and pipes, and causes other problems.

In-line (drain) separators DS-1, DS-2, DS-3, and DS-4 separate condensate efficiently by using the centrifugal force of steam or air created by introducing it into a specifically shaped path. Because of the simple structure of the drain separators, pressure loss is minimized, enabling clean, dry steam or air to be fed to equipment.

When steam or air flow enters the drain separator, centrifugal force is generated in the fluid because of the devices internal structural design. The fluid drains along the wall because of the difference in specific gravity with steam or air, eventually striking the baffle. The baffle guides the fluid to the drain outlet and to the trap, which drains it. As a result, small dirt particles and condensate are separated and removed from the system through the bottom drain.

• Cyclone structure maximizes liquid separation efficiency

• Pressure loss is extremely low

• No moving parts means no breakdowns

Qty:

Part #:501-D47466

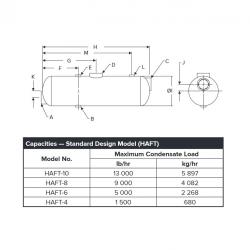

- Vertical (VAFT) and Horizontal (HAFT/HAFT-ST) Flash Tanks • ASME-coded and stamped vessels

• Standard pressure rating 125/150 psi (8.6/10 bar) (Other pressure ratings available.)

• Standard models designed and sized to cover a wide range of applications and loads.

• Flash vessels designed to provide low velocity flash steam with no water carryover.

• Quick payback for flash recovery investment.

• Special tanks available. Consult Armstrong or your Representative.

Qty:

Part #:501-D47467

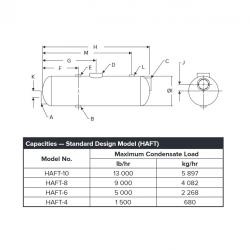

- Vertical (VAFT) and Horizontal (HAFT/HAFT-ST) Flash Tanks • ASME-coded and stamped vessels

• Standard pressure rating 125/150 psi (8.6/10 bar) (Other pressure ratings available.)

• Standard models designed and sized to cover a wide range of applications and loads.

• Flash vessels designed to provide low velocity flash steam with no water carryover.

• Quick payback for flash recovery investment.

• Special tanks available. Consult Armstrong or your Representative.

Qty:

Part #:501-D47468

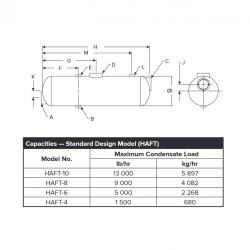

- Vertical (VAFT) and Horizontal (HAFT/HAFT-ST) Flash Tanks • ASME-coded and stamped vessels

• Standard pressure rating 125/150 psi (8.6/10 bar) (Other pressure ratings available.)

• Standard models designed and sized to cover a wide range of applications and loads.

• Flash vessels designed to provide low velocity flash steam with no water carryover.

• Quick payback for flash recovery investment.

• Special tanks available. Consult Armstrong or your Representative.

Qty:

Part #:501-D47469

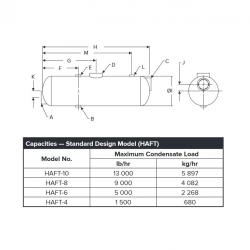

- Vertical (VAFT) and Horizontal (HAFT/HAFT-ST) Flash Tanks • ASME-coded and stamped vessels

• Standard pressure rating 125/150 psi (8.6/10 bar) (Other pressure ratings available.)

• Standard models designed and sized to cover a wide range of applications and loads.

• Flash vessels designed to provide low velocity flash steam with no water carryover.

• Quick payback for flash recovery investment.

• Special tanks available. Consult Armstrong or your Representative.

Qty:

Part #:501-D49536

- Vertical (VAFT) and Horizontal (HAFT/HAFT-ST) Flash Tanks • ASME-coded and stamped vessels

• Standard pressure rating 125/150 psi (8.6/10 bar) (Other pressure ratings available.)

• Standard models designed and sized to cover a wide range of applications and loads.

• Flash vessels designed to provide low velocity flash steam with no water carryover.

• Quick payback for flash recovery investment.

• Special tanks available. Consult Armstrong or your Representative.

Qty:

Part #:501-D49537

- Vertical (VAFT) and Horizontal (HAFT/HAFT-ST) Flash Tanks • ASME-coded and stamped vessels

• Standard pressure rating 125/150 psi (8.6/10 bar) (Other pressure ratings available.)

• Standard models designed and sized to cover a wide range of applications and loads.

• Flash vessels designed to provide low velocity flash steam with no water carryover.

• Quick payback for flash recovery investment.

• Special tanks available. Consult Armstrong or your Representative.

Qty:

Part #:501-D49538

- Vertical (VAFT) and Horizontal (HAFT/HAFT-ST) Flash Tanks • ASME-coded and stamped vessels

• Standard pressure rating 125/150 psi (8.6/10 bar) (Other pressure ratings available.)

• Standard models designed and sized to cover a wide range of applications and loads.

• Flash vessels designed to provide low velocity flash steam with no water carryover.

• Quick payback for flash recovery investment.

• Special tanks available. Consult Armstrong or your Representative.

Qty:

Part #:501-D49539

- Vertical (VAFT) and Horizontal (HAFT/HAFT-ST) Flash Tanks • ASME-coded and stamped vessels

• Standard pressure rating 125/150 psi (8.6/10 bar) (Other pressure ratings available.)

• Standard models designed and sized to cover a wide range of applications and loads.

• Flash vessels designed to provide low velocity flash steam with no water carryover.

• Quick payback for flash recovery investment.

• Special tanks available. Consult Armstrong or your Representative.

Qty:

Displaying: 1 - 13 of 13 Matching Items