Cantex

Armstrong International

View:

Active Filters :

Part #:301354

- CANTEX 6141630 is a 3 in. Schedule 40 Standard Center Stop Coupling used to join lengths of conduit pipe together with two solvent weld socket ends

Features

For use with Schedule 40 and Schedule 80 conduit. May also be used in EB & DB Duct applications.

Center stop to help determine proper depth of connection

For use aboveground and underground and non-conductive and sunlight resistant

Meets NEMA TC-3 Standards

UL and CSA listed

Made in USA

$

1.43

Qty:

Part #:301356

- CANTEX 6141632 is a 4 in. Schedule 40 Standard Center Stop Coupling used to join lengths of conduit pipe together with two solvent weld socket ends

Features

For use with Schedule 40 and Schedule 80 conduit. May also be used in EB & DB Duct applications.

Center stop to help determine proper depth of connection

For use aboveground and underground and non-conductive and sunlight resistant

Meets NEMA TC-3 Standards

UL and CSA listed

Made in USA

$

4.62

Qty:

Part #:301402

- CANTEX 5140112 is a 4 in. Male Terminal Adapter which is a connector used to transition from a spigot end PVC conduit to a threaded metal or PVC plastic female bell end

Features

Durable non-conductive PVC will not rust or corrode

For use with Schedule 40 and Schedule 80 conduit. May also be used in EB & DB Duct applications.

Meets NEMA TC-3 Standards

UL and CSA listed

Made in USA

$

3.02

Qty:

Part #:301405

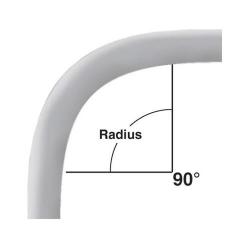

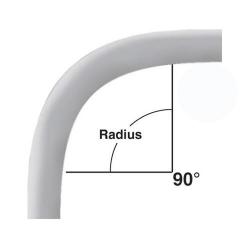

- CANTEX 5133828 is a 2 in. x 90-Degree Plain End Schedule 40 Standard Radius Elbow used to change the direction of a conduit run by 90-Degree

Features

Schedule 40 Nonmetallic PVC construction for strength and durability

For indoor or outdoor use

Suitable for aboveground or buried

Plain-end connections are solvent weld

ETL listed Conforms to UL 651 and NEMA TC-3 Conforms to UL 651 and NEMA TC-3

Made in USA

$

2.09

Qty:

Part #:301414

- CANTEX 5133832 is a 4 in. x 90-Degree Plain End Schedule 40 Standard Radius Elbow used to change the direction of a conduit run by 90-Degree

Features

Schedule 40 Nonmetallic PVC construction for strength and durability

For indoor or outdoor use

Suitable for aboveground or buried

Plain-end connections are solvent weld

ETL listed Conforms to UL 651 and NEMA TC-3 Conforms to UL 651 and NEMA TC-3

Made in USA

$

28.17

Qty:

Part #:301487

- CANTEX 5133821 is a 4 in. x 90-Degree x 36 in. Radius Plain End Schedule 40 Special Radius Elbow used to change the direction of a conduit run by 90-Degree

Features

Schedule 40 Nonmetallic PVC construction for strength and durability

For indoor or outdoor use

Suitable for aboveground or buried

Plain-end connections are solvent weld

ETL listed Conforms to UL 651 and NEMA TC-3 Conforms to UL 651 and NEMA TC-3

Made in USA

$

87.11

Qty:

Part #:301544

- CANTEX 6441001 is a 1/2 in. Enviro-Flex Straight Liquidtight Connector used to connect Enviro-Flex nonmetallic liquidtight flexible tubing to a box opening or threaded female fitting Features Use with Enviro-Flex Liquid Tight Conduit For use in wet or damp locations Durable non-conductive PVC will not rust or corrode Polypropylene sealing ring UL listed

$

2.45

Qty:

Part #:301770

- CANTEX 5133668 is a 2 in. Conduit Body Type LB which provides pull, splice, and tap access for conductors in a conduit system along with a change in direction Features Type LB Conduit Bodies are used to make a 90-degree turn in a conduit run with one opening on top and one opening exiting from the back opposite the cover Durable non-conductive PVC will not rust or corrode For use with Schedule 40 & 80 conduit Includes lid, gasket, and screws UL listed Made in USA

$

23.33

Qty:

Part #:303374

- CANTEX 5133410 is a 2-Gang Weatherproof Blank Cover designed for use with exposed weatherproof boxes

Features

Includes gasket and screws

For use in wet or damp locations

Durable non-conductive PVC will not rust or corrode

UL listed and UL Marine listed

Made in USA

$

5.50

Qty:

Part #:303756

- CANTEX 5133836 is a 2 in. x 90-Degree x 24 in. Radius Plain End Schedule 40 Special Radius Elbow used to change the direction of a conduit run by 90-Degree

Features

Schedule 40 Nonmetallic PVC construction for strength and durability

For indoor or outdoor use

Suitable for aboveground or buried

Plain-end connections are solvent weld

ETL listed Conforms to UL 651 and NEMA TC-3 Conforms to UL 651 and NEMA TC-3

Made in USA

$

22.99

Qty:

Part #:304347

- CANTEX 5133825 is a 1 in. x 90-Degree Plain End Schedule 40 Standard Radius Elbow used to change the direction of a conduit run by 90-Degree Features Schedule 40 Nonmetallic PVC construction for strength and durability For indoor or outdoor use Suitable for aboveground or buried Plain-end connections are solvent weld ETL listed Conforms to UL 651 and NEMA TC-3 Conforms to UL 651 and NEMA TC-3 Made in USA

$

1.56

Qty:

Part #:305525

- CANTEX 5133743 is a 2 in. Service Entrance Caps which is used as the entry point for overhead power and communication wires into a building

Features

Prevents precipitation from entering the conduit into the building

One 1/2 in. and two 3/4 in. knockouts for wire options

Material is Rigid PVC

UL Listed

Made in USA

$

20.90

Qty:

Part #:305527

- CANTEX 5133735 is a 2 in. Conduit Clamp / Strap which is a U-shaped conduit support used to anchor conduit to interior or exterior surfaces Features Two holes in the feet of the clamp allow mounting the screws or nails Durable non-conductive PVC will not rust or corrode For use with Schedule 40 & 80 conduit UL and CSA listed Made in USA Requires two #10 screws for installation (not included)

$

0.52

Qty:

$

110.67

Qty:

Part #:713360

-

Y-Type Cast Iron Strainers

250 lb Screwed 1/2"-3" Class 125 Flanged 2"-6" Class 250 Flanged 2"-6"

Screen chambers won't leak or crush

Both ends of the chambers are precisely machined. This means perfectly round and smooth seating surfaces, as well as a fixed chamber length. Since the screen seats snugly on the machined surface, no particle bigger than the screen opening can escape around the end of the screen.

Screwed retainers easy in, easy out

Straight threads mean it takes less torque to achieve a tight seal with proper gasket compression. Less torque is also required to remove the retainer. For you, that means less danger of "freezing in" than with hard-to-break tapered pipe threads.

Off-center blowdown connections for better dirt removal

Off-center drains on 2-1/2" and 3" strainers allow you to remove liquid and dirt nearly completely when blowing down the strainer. Also, less liquid will spill when the screen retainer is removed.

Many screen choices

Many screen materials, meshes and perforations are available.

Qty:

Part #:713363

-

Y-Type Cast Iron Strainers

250 lb Screwed 1/2"-3" Class 125 Flanged 2"-6" Class 250 Flanged 2"-6"

Screen chambers won't leak or crush

Both ends of the chambers are precisely machined. This means perfectly round and smooth seating surfaces, as well as a fixed chamber length. Since the screen seats snugly on the machined surface, no particle bigger than the screen opening can escape around the end of the screen.

Screwed retainers easy in, easy out

Straight threads mean it takes less torque to achieve a tight seal with proper gasket compression. Less torque is also required to remove the retainer. For you, that means less danger of "freezing in" than with hard-to-break tapered pipe threads.

Off-center blowdown connections for better dirt removal

Off-center drains on 2-1/2" and 3" strainers allow you to remove liquid and dirt nearly completely when blowing down the strainer. Also, less liquid will spill when the screen retainer is removed.

Many screen choices

Many screen materials, meshes and perforations are available.

Qty:

Part #:713364

-

Y-Type Cast Iron Strainers

250 lb Screwed 1/2"-3" Class 125 Flanged 2"-6" Class 250 Flanged 2"-6"

Screen chambers won't leak or crush

Both ends of the chambers are precisely machined. This means perfectly round and smooth seating surfaces, as well as a fixed chamber length. Since the screen seats snugly on the machined surface, no particle bigger than the screen opening can escape around the end of the screen.

Screwed retainers easy in, easy out

Straight threads mean it takes less torque to achieve a tight seal with proper gasket compression. Less torque is also required to remove the retainer. For you, that means less danger of "freezing in" than with hard-to-break tapered pipe threads.

Off-center blowdown connections for better dirt removal

Off-center drains on 2-1/2" and 3" strainers allow you to remove liquid and dirt nearly completely when blowing down the strainer. Also, less liquid will spill when the screen retainer is removed.

Many screen choices

Many screen materials, meshes and perforations are available.

Qty:

Part #:713365

Qty:

Part #:713366

-

Y-Type Cast Iron Strainers

250 lb Screwed 1/2"-3" Class 125 Flanged 2"-6" Class 250 Flanged 2"-6"

Screen chambers won't leak or crush

Both ends of the chambers are precisely machined. This means perfectly round and smooth seating surfaces, as well as a fixed chamber length. Since the screen seats snugly on the machined surface, no particle bigger than the screen opening can escape around the end of the screen.

Screwed retainers easy in, easy out

Straight threads mean it takes less torque to achieve a tight seal with proper gasket compression. Less torque is also required to remove the retainer. For you, that means less danger of "freezing in" than with hard-to-break tapered pipe threads.

Off-center blowdown connections for better dirt removal

Off-center drains on 2-1/2" and 3" strainers allow you to remove liquid and dirt nearly completely when blowing down the strainer. Also, less liquid will spill when the screen retainer is removed.

Many screen choices

Many screen materials, meshes and perforations are available.

Qty:

Part #:334-2721212C

- Male NPT x Push-on Hose Barb Attributes

Weight

0.194 lb

Material

Brass

Component Material

Yellow Plastic Cap

Male Thread

NPTF

Temperature Range

-40°F to 150°F

Length

2.55"

Hose ID

3/4"

Hex

1-1/16"

Male Thread Size

3/4"-14

Pressure Rating

350 PSI

$

6.38

Qty:

Part #:104403

- Conical Muffler Attributes

Maximum Operating Pressure

300 PSI

Weight

0.0355 lb

Material

Nickel Plated Steel

Male Thread

NPT

Temperature Range

35°F to 300°F (1.7°C to 149°C)

Length

1-3/8"

Male Thread Size

1/4"

$

2.67

Qty:

Part #:100696

- SSE31 - Stretch Strap

Attributes

Weight

0.36 lb

Break Quantity

0

Optional Package/Box Quantity

0

Length

31"

$

3.06

Qty:

Part #:713381

- Float and Thermostatic (F&T) Steam TrapsThe More Your Steam Pressure Varies, The More You Need Armstrong F&T TrapsWhen steam pressure may vary from maximum steam supply pressure to vacuum, Armstrong F&Ts are your most energy-efficient choice. Our line of F&Ts brings Armstrong performance, dependability and long life to trapping services requiring continuous drainage with high air venting capacity. Thanks to separate orifices for condensate and air, they provide continuous condensate drainage and air venting-even under conditions of zero pressure. All the benefits detailed here have been designed into Armstrong F&Ts through long experience in the manufacture of pressure float-type traps. They assure you of optimum operating efficiency for long periods with minimum trouble. How they work Float and thermostatic traps are mechanical units that operate on both density and temperature principles. The float valve operates on the density principle. A level connects the ball float to the valve and seat. Once condensate reaches a certain level in the trap, the float rises, opening the orifice and draining condensate. A water seal formed by the condensate prevents live steam loss. Since the discharge valve is under water, it is not capable of venting air and non-condensables. When the accumulation of air and con-condensable gases causes a significant temperature drop, a thermostatic air vent in the top of the trap discharges them. The thermostatic vent opens at a temperature a few degrees below saturation, so it's able to handle a large volume of air-through an entirely separate orifice-but at a slightly reduced temperature. Built as tough as the jobs they do Armstrong float and thermostatic traps are unique in their super heavy duty construction. Armstrong uses high quality ASTM A48 Class 30 cast iron or ASTM A216 WCB cast steel-normally found in pressure vessels rated to 250 psi (17 bar) or 465 psi (32 bar). Internal mechanisms are made from stainless steel and are heavily reinforced. No brass cotter pins here. Valves and seats are stainless steel, hardened, ground and lapped to withstand the erosive forces of flashing condensate. Why go to all this trouble for traps normally recommended for low-pressure, modulating service? The operative word here is modulating. Modulating pressures mean widely varying loads, thermal cycling and high air and non-condensable gas loads. In other words tough service. Inferior, lightweight construction in this kind of service is a mistake waiting to happen. Trap failures on modulating pressure may lead to water hammer, corrosion and even damage to heat exchangers. Armstrong's published capacities are based on actual measurements of traps handling hot, flashing condensate. Competitive F&Ts may utilize theoretical calculated capacities. Armstrong uses its own steam lab to give you actual capacity-especially important on high-capacity traps such as those in our ultra-capacity line. Not only does Armstrong offer super heavy duty construction for long life and reliability, but we also supply the data to back up performance. Here's a simple, easy-to-remember summary The more your pressure varies, the more you need Armstrong F&Ts.

Qty:

Qty:

Displaying: 25 - 48 of 2,429 Matching Items