Armstrong International

Campbell

View:

Active Filters :

- Brand: Campbell Armstrong International General Tool GPK Products

- Size: 3/8in

Part #:508023

-

3/8" Grade 30 Proof Coil Chain, Zinc Plated, 63' per Round Pail

Excellent Low Carbon Steel Chain for General Purpose Applications

Frequently Used for Fabricating Tow Chains, Binding and Logging Chains, Marine and Other General Applications

Standard Finish Zinc Plated or Galvanized

Hallmarking "C3" and "USA" on 5/16" and Larger

Proof Tested

Design Factor 4 to 1

Packaged in Pails, Order Unit is "Each"

Made in the USA

Do Not Use for Overhead Lifting

DO NOT EXCEED THE WORKING LOAD LIMIT

Qty:

Part #:511893

-

3/8" Anchor Shackle, Screw Pin, Forged Carbon Steel, Painted Blue

Shackle Bodies Are Drop-Forged Carbon Steel

Self Colored (Painted Blue)

C-419-S Shackles Meet the Design Requirements of Federal Specification RR-C-271, Type IVA, Grade A, Class 2

Working Load Limit, Size, Manufacture Name, Date Code and USA Permanently Marked on Each Shackle

Statistically Tested for Impact Resistance, Tensile Strength, Hardness, Ductility and Fatigue

419 Series Shackles Meet or Exceed All Manufacturing Requirements of the ASME B30.26 &rdquoRigging Hardware&rdquo. These Include the Material Ductility Requirement (Section 26-1.1.2), the Design Factor Requirement (Section 26.1.2), the Identification Requirement (Section 26-1.5.1), and the Effective Temperature Range (Section 26-1.6.1). the Shackles Can Be Proof Tested in Accordance with Section 26-1.4

Certification Available Upon Request

6 to 1 Design Factor

Pins and Bolts Are Heat-Treated and Made of Alloy Steel

DO NOT EXCEED THE WORKING LOAD LIMIT

Qty:

Part #:511864

-

3/8" Clevis Grab Hook, Grade 43, Zinc Plated

Forged Steel

Grade 43

UPC Tagged

Grab Hooks Are Designed to Grab a Chain Link and Hold it in Place

Hooks are Sized by the Material Diameter of the Chain That They Engage. Make Sure the Hook Size and Chain Diameter are Compatible Before Attaching to Load

DO NOT EXCEED THE WORKING LOAD LIMIT

Qty:

Part #:500671

- 3/8" Alloy Clevis Grab Hook, Forged Alloy, Painted Orange

Material is Drop-Forged Carbon Steel (Grade 30 & 43) or Heat-Treated Alloy Steel

Grade 30 & 43 Hooks Available Self-Colored or Zinc-Plated

Alloy Hooks Are Painted Orange and Stamped &rdquoAlloy&rdquo 3.5 to 1 Design Factor

Alloy Hook Sizes 1/4" to 3/8" are Supplied Individually Bagged and Unassembled

Self-Colored Finish Hooks Are Bulk Packed, Zinc Plated Hooks Are Packed 10 Per Box

Grab Hooks Are Designed to Grab a Chain Link and Hold it in Place

Hooks are Sized by the Material Diameter of the Chain That They Engage. Make Sure the Hook Size and Chain Diameter are Compatible Before Attaching to Load

DO NOT EXCEED THE WORKING LOAD LIMIT

Qty:

Part #:502810

-

3/8" Grade 30 Proof Coil Chain, Zinc Plated, 63' per Round Pail

Excellent Low Carbon Steel Chain for General Purpose Applications

Frequently Used for Fabricating Tow Chains, Binding and Logging Chains, Marine and Other General Applications

Standard Finish Zinc Plated or Galvanized

Hallmarking "C3" and "USA" on 5/16" and Larger

Proof Tested

Design Factor 4 to 1

Packaged in Pails, Order Unit is "Each"

Made in the USA

Do Not Use for Overhead Lifting

DO NOT EXCEED THE WORKING LOAD LIMIT

Qty:

closeout

$11.73 MSRP

$

10.35

Part #:511844

- CLOSEOUTS Only 35 Left!

-

3/8" Wire Rope Clip, Forged Carbon Steel, Galvanized (Discontinued being replaced by 490-M248-2)

Base is Drop-Forged Carbon Steel

Hot Galvanized to ASTM A-153 to Resist Rust and Corrosion

U-Bolts Are colored Blue for Identification Purposes and Use Heavy Duty Hex Nuts (UNC-2A)

Designed to Meet Federal Specifications, FF-C-450, Type 1, Class 1

Designed to Meet or Exceed All Requirements of ASME B30.26 Including Identification, Ductility, Design Factor and Temperature

Permanently Marked with Size and Manufacturer

Sizes 1/4" and Above Marked with USA and Date Code

Sizes 1/8" Through 1-1/4" Are Supplied Bagged and Unassembled

Note See Application and Warning Information

Qty:

Part #:507004

-

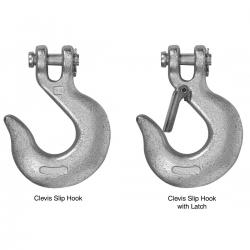

3/8" Clevis Slip Hook, Grade 43, Zinc Plated

Forged Steel

Grade 43

UPC Tagged

Slip Hooks Are Designed to Allow Chain to Slip Through the Hook

Hooks are Sized by the Material Diameter of the Chain That They Engage. Make Sure the Hook Size and Chain Diameter are Compatible Before Attaching to Load

Qty:

closeout

$18.88 MSRP

$

11.08

Part #:511872

- CLOSEOUTS Only 8 Left!

-

3/8" Connecting Link, Forged Carbon Steel, Self Colored, 10 Pcs per Box

Drop-Forged Heat-Treated Carbon or Alloy Steel

Standard Finish is Self-Colored or Galvanized to Meet ASTM A-153 Specifications

4 to 1 Design Factor

For Proper Closure, Peen the Prongs to Fill the Hole of the Mating Half as Much as Possible

Meets Design Requirements of Federal Specification RR-C-271D, Type II

Make Sure the Connecting Link Used is the Same Size as the Components Being Joined. e.g., a 3/8 in. Connecting Link is Used with 3/8 in. Chain

Any Assembly Made Using Connecting Links Should be Rated at the Working Load Limit of the Weakest Component.

The Working Load Limit of Connecting Links is Based on a Straight Line Pull. Any Side or Shock Loading Will Significantly Reduce the Actual Working Load Limit.

NEVER Re-Use a Connecting Link

DO NOT EXCEED THE WORKING LOAD LIMIT

Qty:

Part #:511927

-

3/8" Eye Slip Hook, Grade 43, Zinc Plated

Forged Steel

Grade 43

UPC Tagged

Slip Hooks Are Designed to Allow Chain to Slip Through the Hook

DO NOT EXCEED THE WORKING LOAD LIMIT

Qty:

Part #:511942

-

3/8" Heavy Wire Rope Thimble, Galvanized

Standard Material Hot Rolled, Mild Steel

Galvanized

Imported

A Thimble is a Wear Pad That Protects the Rope From Cuts, Kinking and Abrasions. Always Use An Appropriate Thimble When Making An Eye in a Rope.

When it is Necessary to Open a Thimble to Insert a Fitting, Make Sure the Points are Properly Aligned When the Thimble is Closed. Inspect Carefully for Cracks.

Thimbles ARE NOT Designed for Load Carrying Purposes Therefore Working Load Limits Have Not Been Established.

Qty:

Qty:

Part #:501-D500578

- CD-40 and CD-60 Series Controlled Disc Steam TrapsFor pressures to 600 psig (41 barg)

Capacities to 2,850 lb/hr (1 295 kg/hr)

Armstrong CD-40 and CD-60 Series controlled disc traps contain a replaceable capsule, making it possible to renew a worn trap by simply replacing the capsule. A heating chamber in the shell ensures consistent operation. This steam jacket provides a relatively constant temperature in the control chamber regardless of ambient conditions. Cycling rate is controlled and does not increase when the trap is exposed to cold winds, rain or snow. CD-40 Series traps are also available with optional integral .045 perforated stainless steel strainer screens. CD-60 Series traps contain integral strainers with ratios of open area to inside area of pipe that equal or exceed those of most separate Y-type strainers.

Qty:

Part #:501-D503146

- Inverted Bucket Steam TrapsEnergy efficient because it's so reliable

The inverted bucket is the most reliable steam trap operating principle known. The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure.

Since the bucket is open at the bottom, it resists damage from water hammer, and wear points are heavily reinforced for long life. The inverted bucket has only two moving parts-the valve lever assembly and the bucket. That means no fixed points, no complicated linkage. Nothing to stick, bind or clog.

Conserves energy even in the presence of wear

Armstrong inverted bucket steam traps open and close based on the difference in density between condensate and steam-the inverted bucket principle. They open and close gently, minimizing wear. This simple fact means that inverted buckets are subject to less wear than some other types of traps.

In fact, as an Armstrong inverted bucket trap wears, its tight seal actually improves. The valve and seat of the Armstrong trap provide essentially line contact-resulting in a tight seal because the entire closing force is concentrated on one narrow seating ring.

An Armstrong inverted bucket steam trap continues to operate efficiently with use. Gradual wear slightly increases the diameter of the seat and alters the shape and diameter of the valve. But, as this occurs, a tight seal is still preserved-the ball merely seats itself more deeply.

Corrosion-resistant parts

The stainless steel valve and seat of the Armstrong inverted bucket steam trap are individually ground and lapped together in matched sets. All other working parts are wear- and corrosion-resistant stainless steel.

Venting of air and CO2

The Armstrong inverted bucket provides continuous automatic air and CO2 venting with no cooling lag or threat of air binding.

Operation against back pressure

The Armstrong inverted bucket has excellent performance against back pressure. It has no adverse effect on inverted bucket operation other than to reduce its capacity by the low differential. The bucket simply requires less force to pull the valve open and cycle the trap.

Freedom from dirt problems

Armstrong designed its inverted bucket to be virtually free of dirt problems. The valve and seat are at the top of the trap, far away from the larger particles of dirt, which fall to the bottom. Here, the up-and-down action of the bucket pulverizes them.

Since the valve of an inverted bucket is either fully closed or open, dirt particles pass freely. And the swift flow of condensate from under the bucket's edge creates a unique self-scrubbing action that sweeps dirt out of the trap.

Qty:

Part #:501-D541398

- Thermostatic Wafer Steam TrapsArmstrong offers several thermostatic wafer steam traps. The WT-1 is ideal for low-capacity steam tracers and features an exclusive non-welded wafer design, a sealed stainless steel body and an internal strainer screen two to three times larger than that of other thermostatic traps. Choose from NPT or BSPT screwed connections.

The WT-2000 is adaptable to a 360 connector to expand piping options and simplify installation. Choose NPT or BSPT screwed or socketweld connections. The WT-2000 is also available for use on the IS-2 stainless steel connector with integral strainer. It can also be used with the TVS 4000.

Armstrongs WT-3 is a carbon steel thermostatic wafer trap for superheated drip service. It features an exclusive non-welded wafer design, which eliminates problems associated with weld stress. The WT-3 has no thin-walled enclosures such as bellows or welded diaphragms. It is also resistant to water hammer. Choose NPT or BSPT screwed or socketweld connections.

The Series MT from Armstrong is sized precisely to accommodate the extremely low condensate loads found in most instrument steam tracer lines.

NOTE Since the normal operation of all suppressed temperature-discharge (subcooling) steam traps is to back up condensate, they should not be used on drip legs for saturated steam service, heating or process equipment. Exercise care in the maintenance of any thermostatic wafer trap with a small discharge area susceptible to clogging.

Qty:

Part #:501-D691280

- Inverted Bucket Steam TrapsEnergy efficient because it's so reliable

The inverted bucket is the most reliable steam trap operating principle known. The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure.

Since the bucket is open at the bottom, it resists damage from water hammer, and wear points are heavily reinforced for long life. The inverted bucket has only two moving parts-the valve lever assembly and the bucket. That means no fixed points, no complicated linkage. Nothing to stick, bind or clog.

Conserves energy even in the presence of wear

Armstrong inverted bucket steam traps open and close based on the difference in density between condensate and steam-the inverted bucket principle. They open and close gently, minimizing wear. This simple fact means that inverted buckets are subject to less wear than some other types of traps.

In fact, as an Armstrong inverted bucket trap wears, its tight seal actually improves. The valve and seat of the Armstrong trap provide essentially line contact-resulting in a tight seal because the entire closing force is concentrated on one narrow seating ring.

An Armstrong inverted bucket steam trap continues to operate efficiently with use. Gradual wear slightly increases the diameter of the seat and alters the shape and diameter of the valve. But, as this occurs, a tight seal is still preserved-the ball merely seats itself more deeply.

Corrosion-resistant parts

The stainless steel valve and seat of the Armstrong inverted bucket steam trap are individually ground and lapped together in matched sets. All other working parts are wear- and corrosion-resistant stainless steel.

Venting of air and CO2

The Armstrong inverted bucket provides continuous automatic air and CO2 venting with no cooling lag or threat of air binding.

Operation against back pressure

The Armstrong inverted bucket has excellent performance against back pressure. It has no adverse effect on inverted bucket operation other than to reduce its capacity by the low differential. The bucket simply requires less force to pull the valve open and cycle the trap.

Freedom from dirt problems

Armstrong designed its inverted bucket to be virtually free of dirt problems. The valve and seat are at the top of the trap, far away from the larger particles of dirt, which fall to the bottom. Here, the up-and-down action of the bucket pulverizes them.

Since the valve of an inverted bucket is either fully closed or open, dirt particles pass freely. And the swift flow of condensate from under the bucket's edge creates a unique self-scrubbing action that sweeps dirt out of the trap.

Qty:

Part #:764502

-

3/8" Spring Snap Link, Steel, Zinc Plated, #2450

Ideal for Hanging Keys and Other Utility Items From Belt

Fast and Easy to Connect and Disconnect

DO NOT EXCEED THE WORKING LOAD LIMIT

Do Not Use for Overhead Lifting or Hoisting

Do Not Use to Support Human Weight, for Playground or Athletic Equipment, or as a Safety Device

Qty:

Part #:713386

- CD-33 Series Disc Steam TrapFor steam service up to 600 psig (42 barg) Capacities to 2,500 lb/hr (1,134 kg/hr). The Armstrong CD-33 is a disc-style trap designed to control the trap&rsquos cycle rate. By reducing the cycle rate, the Armstrong CD-33 extends its service life well beyond that of typical disc traps. This enhanced performance minimizes maintenance time and greatly reduces steam costs. The CD-33 is designed with three discharge ports, which offer stable disc operation to extend operating life. The capacities of the Armstrong CD-33 have been engineered specifically for the following applications large steam main drips, process equipment and HVAC heating equipment on constant pressure. The CD-33L (low capacity) trap is designed for the low capacity applications of steam main drips and steam tracing lines. By ensuring that the capacities are designed to suit the application&mdashand are not oversized&mdashthe CD-33 Series will last longer than other disc traps with excessive capacity ratings. Here&rsquos why &bull Three-discharge port design &bull Minimum wear with controlled cycling &bull Freeze resistant &bull Hardened seat and disc

Qty:

Part #:806808

-

3/8" Quick Link, Steel, Zinc Plated, #7350

For Fast and Easy Connections Between Two Lengths of Chain

DO NOT EXCEED THE WORKING LOAD LIMIT

Do Not Use for Overhead Lifting or Hoisting

Do Not Use to Support Human Weight, for Playground or Athletic Equipment, or as a Safety Device

Qty:

Part #:690-T9600635

- 3/8" Anchor Shackle, Screw Pin, Zinc Plated

Carbon Steel

UPC Tagged

DO NOT EXCEED THE WORKING LOAD LIMIT

Do Not Use for Overhead Lifting or Hoisting

Qty:

Displaying: 1 - 19 of 19 Matching Items