Product Description

Armstrong automatic differential condensate controllers (DC) are designed to function on applications where condensate must be lifted from a drain point or in gravity drainage applications where increased velocity will aid in condensate drainage. Lifting condensate from the drain point—often referred to as siphon drainage—reduces the pressure of the condensate, causing a portion of it to flash into steam. Since ordinary steam traps are unable to distinguish flash steam from live steam, they close and impeded drainage. Increased velocity with gravity drainage will aid in drawing the condensate and air to the DC. An internal steam bypass controlled by a manual metering valve causes this increased velocity. Therefore, the condensate controller automatically vents the bypass or secondary steam. This steam is then collected for use in other heat exchangers or discharged to the condensate return line. Capacity considerations for draining equipment vary greatly, according to the application. However, a single condensate controller provides sufficient capacity for most applications..

How they work

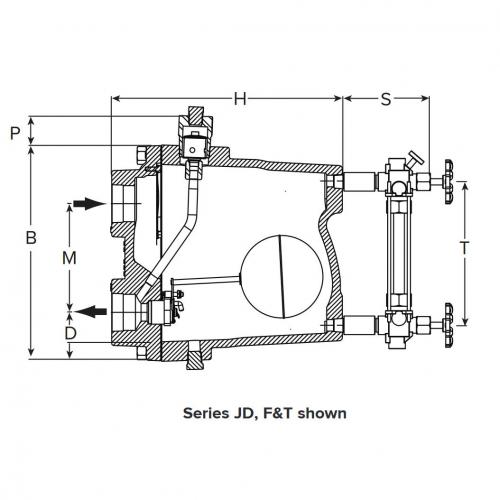

Condensate, air and steam (live and flash) enter through the controller inlet. At this point, flash steam and air are automatically separated from the condensate. Then they divert into the integral bypass at a controlled rate, forming secondary steam.

The valve is adjustable so it matches the amount of flash present under full capacity operation or to meet the velocity requirements of the system. The condensate discharges through a separate orifice by the inverted bucket.

Because of the dual-orifice design, there is a preset controlled pressure differential for the secondary steam system, while maximum pressure differential is available to discharge the condensate.

Product Specifications

- Main Category: Steam and Filter Products

- Brand: Armstrong International

- Brand: Armstrong

- Size: 2in

- Weight (lbs): 80.00

- Material: Ductile Iron

- Steam Traps: Float and Thermostatic Traps (F&T)

- Orifice Size: 7/16in

- End Connection: Threaded

- Maximum Operating Pressure (psi): 175psi

- Series: JD

- Model: 175JD8

- Part Number: C6125

- Alt. Size: 2"

Applications/Usage & Features

Cast Iron for Horizontal Application

For pressures from vacuum to 300 psig (21 bar)

Capacities to 142,000 lb/hr (64,400 kg/hr)

The simple, yet rugged, ductile iron construction of the JD & KD Series Automatic Differential Condensate Controller offers long, trouble-free service. All floats, valves and seats, and lever mechanisms are constructed of stainless steel.

The integral thermostatic air vent is a balanced-pressure phosphor-bronze bellows caged in stainless steel. It is designed especially for demanding industrial applications where highly efficient, uninterrupted service is essential. This balanced-pressure type of air vent will respond to the pressure-temperature curve of steam at any pressure from zero to 175 psig (12 bar). Thus—up to 175 psig (12 bar)—air is vented at slightly below steam temperature.

The condensate controller with flash release is for syphon drainage and/or cascade service. The condensate controller (CC) configuration was developed especially to meet very large capacity needs in applications where condensate must be lifted from the drain point to the trap. Under such conditions—often referred to as syphon drainage—the reduction in pressure that occurs when the condensate is elevated causes a portion of the condensate to flash into steam. Ordinary traps, unable to differentiate between flash steam and live steam, close and impede drainage.

The JD & KD Series condensate controllers (CC) are equipped with a fixed restricted orifice near the top of the body to bleed off the flash steam (and all air present). This permits the trap to function properly on condensate.