Product Description

The More Your Steam Pressure Varies, The More You Need Armstrong F&T Traps

When steam pressure may vary from maximum steam supply pressure to vacuum, Armstrong F&Ts are your most energy-efficient choice. Our line of F&Ts brings Armstrong performance, dependability and long life to trapping services requiring continuous drainage with high air venting capacity. Thanks to separate orifices for condensate and air, they provide continuous condensate drainage and air venting-even under conditions of zero pressure.

All the benefits detailed here have been designed into Armstrong F&Ts through long experience in the manufacture of pressure float-type traps. They assure you of optimum operating efficiency for long periods with minimum trouble.

How they work

Float and thermostatic traps are mechanical units that operate on both density and temperature principles. The float valve operates on the density principle. A level connects the ball float to the valve and seat. Once condensate reaches a certain level in the trap, the float rises, opening the orifice and draining condensate. A water seal formed by the condensate prevents live steam loss.

Since the discharge valve is under water, it is not capable of venting air and non-condensables. When the accumulation of air and con-condensable gases causes a significant temperature drop, a thermostatic air vent in the top of the trap discharges them. The thermostatic vent opens at a temperature a few degrees below saturation, so it's able to handle a large volume of air-through an entirely separate orifice-but at a slightly reduced temperature.

Built as tough as the jobs they do

Armstrong float and thermostatic traps are unique in their super heavy duty construction. Armstrong uses high quality ASTM A48 Class 30 cast iron or ASTM A216 WCB cast steel-normally found in pressure vessels rated to 250 psi (17 bar) or 465 psi (32 bar). Internal mechanisms are made from stainless steel and are heavily reinforced. No brass cotter pins here. Valves and seats are stainless steel, hardened, ground and lapped to withstand the erosive forces of flashing condensate.

Why go to all this trouble for traps normally recommended for low-pressure, modulating service? The operative word here is modulating. Modulating pressures mean widely varying loads, thermal cycling and high air and non-condensable gas loads.

In other words: tough service. Inferior, lightweight construction in this kind of service is a mistake waiting to happen. Trap failures on modulating pressure may lead to water hammer, corrosion and even damage to heat exchangers.

Armstrong's published capacities are based on actual measurements of traps handling hot, flashing condensate. Competitive F&Ts may utilize theoretical calculated capacities. Armstrong uses its own steam lab to give you actual capacity-especially important on high-capacity traps such as those in our ultra-capacity line. Not only does Armstrong offer super heavy duty construction for long life and reliability, but we also supply the data to back up performance. Here's a simple, easy-to-remember summary: The more your pressure varies, the more you need Armstrong F&Ts.

Product Specifications

- Main Category: Steam and Filter Products

- Brand: Armstrong International

- Brand: Armstrong

- Size: 1/2in

- Weight (lbs): 23.00

- Material: Carbon Steel

- Steam Traps: Float and Thermostatic Traps (F&T)

- Orifice Size: 11/64in

- End Connection: Flanged

- Pressure Class: 125lb/150lb

- Series: ICS

- Model: 75ICS2

- Part Number: D34505

- Alt. Size: 1/2"

Applications/Usage & Features

Carbon Steel for Horizontal or Vertical Installation with Thermostatic Air Vent

For pressures to 465 psig (32 barg)

Capacities to 60,000 lb/hr (27,215 kg/hr)

Armstrong ICS Series F&T traps are for industrial service from 0 to 465 psig (32 bar). The simple yet rugged construction of the ICS series carbon steel float and thermostatic trap is designed to assure long, trouble-free service.

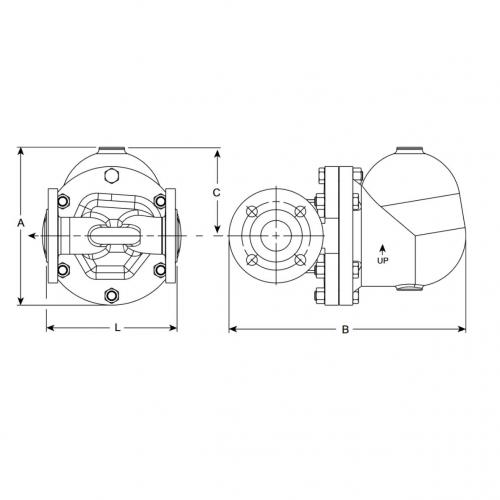

The ICS Float and Thermostatic Steam Trap is used for continuous drainage of condensate and high-capacity venting of air and CO2, when steam pressure may vary from maximum steam supply pressure to vacuum. Armstrong ICS F&T Steam trap is available with flanged connections of 150RF, 300RF & PN40RF, socket weld and screwed connections in 1/2’’, 3/4’’, 1’’, 1-1/2’’ and 2’’ sizes for the maximum operating pressure range of 75 psig (5 barg) to 465 psig (32 barg).