2-3/16in

1/4

View:

Active Filters :

- Size: 1/4 2-3/16in 2in x 3/4in

Part #:307261

- Appleton™ Type RW steel reducing washers are used to reduce the size of a knockout or slip hole in a sheet metal enclosure to a smaller trade size..

$

2.17

Qty:

$

24.98

Qty:

Qty:

Qty:

Qty:

Qty:

Qty:

Qty:

Qty:

Qty:

Qty:

$

38.49

Qty:

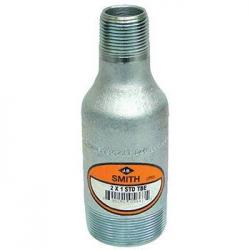

Part #:307093

- Appleton RB Series reducers are explosionproof and dust-ignitionproof. They are designed to reduce conduit entries to a smaller size and are used in threaded rigid and IMC conduit systems.

$

28.40

Qty:

Qty:

Qty:

$

71.21

Qty:

Qty:

Part #:204232

- All Fittings Meet or Exceed

&bull Materials ASTM D-1784, NSF Approved for potable water, NSF 61 &bull Joints ASTM D-3139 &bull Gaskets ASTM F-477 &bull Wall Thickness SDR-21 &bull Pressure Rating 200psi

Qty:

Qty:

Part #:1267-18-110-025-0/180-F/C

- ApplicationUsed in almost every area of manufacturing, especially suited for applications in the following areasIndustrial processPetrochemicalFood & beverage processingCommercialWastewaterLimitations Which Apply AreThese units must be operated within the catalogued environmental and application parameters. Determination of failure will be made by NOSHOK, Inc.'s equipment and personnel or a certified test facility specializing in this type of evaluation.In keeping with and for purposes of product and/or manufacturing process improvements, NOSHOK, Inc. reserves the right to make design changes without prior notice.NoteThermowells are recommended for pressure, corrosive fluids and high velocity applications.

Qty:

Part #:1267-18-110-025-0/200-F

- ApplicationUsed in almost every area of manufacturing, especially suited for applications in the following areasIndustrial processPetrochemicalFood & beverage processingCommercialWastewaterLimitations Which Apply AreThese units must be operated within the catalogued environmental and application parameters. Determination of failure will be made by NOSHOK, Inc.'s equipment and personnel or a certified test facility specializing in this type of evaluation.In keeping with and for purposes of product and/or manufacturing process improvements, NOSHOK, Inc. reserves the right to make design changes without prior notice.NoteThermowells are recommended for pressure, corrosive fluids and high velocity applications.

Qty:

Part #:1267-18-110-060-50/500-F

- ApplicationUsed in almost every area of manufacturing, especially suited for applications in the following areasIndustrial processPetrochemicalFood & beverage processingCommercialWastewaterLimitations Which Apply AreThese units must be operated within the catalogued environmental and application parameters. Determination of failure will be made by NOSHOK, Inc.'s equipment and personnel or a certified test facility specializing in this type of evaluation.In keeping with and for purposes of product and/or manufacturing process improvements, NOSHOK, Inc. reserves the right to make design changes without prior notice.NoteThermowells are recommended for pressure, corrosive fluids and high velocity applications.

Qty:

Part #:1267-2070604-MMS

- Additional Information100% helium leak tested to 1 x 10-4 ml/s for guaranteed performance and reliabilityBlow-out proof stem provides a secondary stem seal in the full open positionFKM o-ring seal and PTFE back-up ring below the stem threads to protect from corrosion and galling PTFE or Graphite packing optionalAll stem threads are rolled for strength and ease of operationOne-piece bonnet with a metal-to-metal seal to the valve body below the bonnet threadsSlotted spring pin to prevent accidental looseningVinyl dust cap for bonnet and stem (non-packing)Additional OptionsStem TipsBall (440C stainless) (T5)Ball (carbide) (T6)Ball (ceramic) (T7)Ball (Monel) (T8)Non-rotating regulating (316 Stainless) (T9)O-RingsEPDM (EM1)FFKM (Perfluoroelastomer 3018 or equivalent) (KZ1)Handles2-1/2" "T" (HL2)1" Round knurled (HL3)1-3/8" Phenolic (HL4)1-3/4" Phenolic (HL5 )Limitations Which Apply AreThese units must be operated within the catalogued environmental and application parameters. Determination of failure will be made by NOSHOK, Inc.'s equipment and personnel or a certified test facility specializing in this type of evaluation.In keeping with and for purposes of product and/or manufacturing process improvements, NOSHOK, Inc. reserves the right to make design changes without prior notice.NotePlease note that the standard o-ring in all the NOSHOK valves is FKM and the standard handles are block "T" handles (HL2) and bleed mini "T" handles (HL1).The handle material will always match the material of the valve, unless otherwise specified. For example, the "T" handle (HL2) on the 2070-FFC will be steel. When only the standard configuration is needed, no additional designations are necessary. Please consult the factory for special application requests.All NOSHOK valve products conform to the MSS SP-99 instrument valves standards, and valves supplied with packing also conform to MSS SP-132 compression packing systems for instrument valves standard.

Qty:

Displaying: 1 - 24 of 568 Matching Items