200psi

50psi

Part #:200534

- Features and Advantages

&bull Sizes 3"-12" are Underwriters Laboratories Inc. Listed at 200 PSI for 3"-8" sizes and 175 PSI for 10"-12" sizes.For use on PC350 ductile iron and SCH40 steel pipe.&bull Bolt hole drilling is to ANSI B16.1 class 125.&bull Uses standard mechanical joint gasket for seal on DI Pipe and Transition Gasket on steel pipe.&bull Pipe fabrication can be done on site, using plain end pipe.&bull Flange Adapters are ideal for jobs involving retro-fitting.&bull Can be used on Ductile Iron (3"-36") and Steel (3"-12") Pipe -- steel pipe sizes require a transition gasket.&bull Can be used in above or below ground applications&bull If future maintenance is required, Flange Adapters can be easily disassembled.

Qty:

Part #:802087

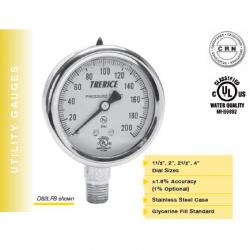

- The Trerice 800B Utility Gauge is designed for general pressure indication requirements. This gauge provides reliable service at an economical cost. Wetted parts are bronze tube and Lead-Free (PBF) brass socket.

Qty:

Part #:807700

- The Trerice D80 Series Industrial Gauge is designed for rugged performance requirements at an economical cost. This liquid filled gauge is furnished with a stainless steel case and crimped ring. Wetted parts are either bronze tube with Lead-Free (PBF) brass socket or stainless steel.

Qty:

Part #:801165

- The Trerice 800B Utility Gauge is designed for general pressure indication requirements. This gauge provides reliable service at an economical cost. Wetted parts are bronze tube and Lead-Free (PBF) brass socket.

Qty:

Part #:200536

- Features and Advantages

&bull Sizes 3"-12" are Underwriters Laboratories Inc. Listed at 200 PSI for 3"-8" sizes and 175 PSI for 10"-12" sizes.For use on PC350 ductile iron and SCH40 steel pipe.&bull Bolt hole drilling is to ANSI B16.1 class 125.&bull Uses standard mechanical joint gasket for seal on DI Pipe and Transition Gasket on steel pipe.&bull Pipe fabrication can be done on site, using plain end pipe.&bull Flange Adapters are ideal for jobs involving retro-fitting.&bull Can be used on Ductile Iron (3"-36") and Steel (3"-12") Pipe -- steel pipe sizes require a transition gasket.&bull Can be used in above or below ground applications&bull If future maintenance is required, Flange Adapters can be easily disassembled.

Qty:

Part #:411-SF403GN

- Features and Advantages

&bull Sizes 3"-12" are Underwriters Laboratories Inc. Listed at 200 PSI for 3"-8" sizes and 175 PSI for 10"-12" sizes.For use on PC350 ductile iron and SCH40 steel pipe.&bull Bolt hole drilling is to ANSI B16.1 class 125.&bull Uses standard mechanical joint gasket for seal on DI Pipe and Transition Gasket on steel pipe.&bull Pipe fabrication can be done on site, using plain end pipe.&bull Flange Adapters are ideal for jobs involving retro-fitting.&bull Can be used on Ductile Iron (3"-36") and Steel (3"-12") Pipe -- steel pipe sizes require a transition gasket.&bull Can be used in above or below ground applications&bull If future maintenance is required, Flange Adapters can be easily disassembled.

Qty:

Part #:207102

- Features and Advantages

&bull Sizes 3"-12" are Underwriters Laboratories Inc. Listed at 200 PSI for 3"-8" sizes and 175 PSI for 10"-12" sizes.For use on PC350 ductile iron and SCH40 steel pipe.&bull Bolt hole drilling is to ANSI B16.1 class 125.&bull Uses standard mechanical joint gasket for seal on DI Pipe and Transition Gasket on steel pipe.&bull Pipe fabrication can be done on site, using plain end pipe.&bull Flange Adapters are ideal for jobs involving retro-fitting.&bull Can be used on Ductile Iron (3"-36") and Steel (3"-12") Pipe -- steel pipe sizes require a transition gasket.&bull Can be used in above or below ground applications&bull If future maintenance is required, Flange Adapters can be easily disassembled.

Qty:

Part #:334-U260

- Tectite&trade by Apollo® Push to Connect Elbow Attributes

Maximum Operating Pressure

200 PSI

Weight

0.48 lb

Material

Forged Brass

Tube Size

1"

Temperature Range

32°F to 250°F (0°C to 121°C)

Maximum Temperature

200°F (93°C)

$

29.84

Qty:

Part #:334-U520

- Tectite&trade by Apollo® Push to Connect End Stop Attributes

Maximum Operating Pressure

200 PSI

Weight

0.27 lb

Material

Forged Brass

Tube Size

1"

Temperature Range

32°F to 250°F (0°C to 121°C)

Maximum Temperature

200°F (93°C)

$

24.58

Qty:

Qty:

Part #:800753

- The Trerice D80 Series Industrial Gauge is designed for rugged performance requirements at an economical cost. This liquid filled gauge is furnished with a stainless steel case and crimped ring. Wetted parts are either bronze tube with Lead-Free (PBF) brass socket or stainless steel.

Qty:

Part #:801952

Qty:

Part #:200537

- Features and Advantages

&bull Sizes 3"-12" are Underwriters Laboratories Inc. Listed at 200 PSI for 3"-8" sizes and 175 PSI for 10"-12" sizes.For use on PC350 ductile iron and SCH40 steel pipe.&bull Bolt hole drilling is to ANSI B16.1 class 125.&bull Uses standard mechanical joint gasket for seal on DI Pipe and Transition Gasket on steel pipe.&bull Pipe fabrication can be done on site, using plain end pipe.&bull Flange Adapters are ideal for jobs involving retro-fitting.&bull Can be used on Ductile Iron (3"-36") and Steel (3"-12") Pipe -- steel pipe sizes require a transition gasket.&bull Can be used in above or below ground applications&bull If future maintenance is required, Flange Adapters can be easily disassembled.

Qty:

Part #:501-C5297-33

- Inverted Bucket Steam TrapsEnergy efficient because it's so reliable

The inverted bucket is the most reliable steam trap operating principle known. The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure.

Since the bucket is open at the bottom, it resists damage from water hammer, and wear points are heavily reinforced for long life. The inverted bucket has only two moving parts-the valve lever assembly and the bucket. That means no fixed points, no complicated linkage. Nothing to stick, bind or clog.

Conserves energy even in the presence of wear

Armstrong inverted bucket steam traps open and close based on the difference in density between condensate and steam-the inverted bucket principle. They open and close gently, minimizing wear. This simple fact means that inverted buckets are subject to less wear than some other types of traps.

In fact, as an Armstrong inverted bucket trap wears, its tight seal actually improves. The valve and seat of the Armstrong trap provide essentially line contact-resulting in a tight seal because the entire closing force is concentrated on one narrow seating ring.

An Armstrong inverted bucket steam trap continues to operate efficiently with use. Gradual wear slightly increases the diameter of the seat and alters the shape and diameter of the valve. But, as this occurs, a tight seal is still preserved-the ball merely seats itself more deeply.

Corrosion-resistant parts

The stainless steel valve and seat of the Armstrong inverted bucket steam trap are individually ground and lapped together in matched sets. All other working parts are wear- and corrosion-resistant stainless steel.

Venting of air and CO2

The Armstrong inverted bucket provides continuous automatic air and CO2 venting with no cooling lag or threat of air binding.

Operation against back pressure

The Armstrong inverted bucket has excellent performance against back pressure. It has no adverse effect on inverted bucket operation other than to reduce its capacity by the low differential. The bucket simply requires less force to pull the valve open and cycle the trap.

Freedom from dirt problems

Armstrong designed its inverted bucket to be virtually free of dirt problems. The valve and seat are at the top of the trap, far away from the larger particles of dirt, which fall to the bottom. Here, the up-and-down action of the bucket pulverizes them.

Since the valve of an inverted bucket is either fully closed or open, dirt particles pass freely. And the swift flow of condensate from under the bucket's edge creates a unique self-scrubbing action that sweeps dirt out of the trap.

Qty:

Part #:501-C5297-51

- Inverted Bucket Steam TrapsEnergy efficient because it's so reliable

The inverted bucket is the most reliable steam trap operating principle known. The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure.

Since the bucket is open at the bottom, it resists damage from water hammer, and wear points are heavily reinforced for long life. The inverted bucket has only two moving parts-the valve lever assembly and the bucket. That means no fixed points, no complicated linkage. Nothing to stick, bind or clog.

Conserves energy even in the presence of wear

Armstrong inverted bucket steam traps open and close based on the difference in density between condensate and steam-the inverted bucket principle. They open and close gently, minimizing wear. This simple fact means that inverted buckets are subject to less wear than some other types of traps.

In fact, as an Armstrong inverted bucket trap wears, its tight seal actually improves. The valve and seat of the Armstrong trap provide essentially line contact-resulting in a tight seal because the entire closing force is concentrated on one narrow seating ring.

An Armstrong inverted bucket steam trap continues to operate efficiently with use. Gradual wear slightly increases the diameter of the seat and alters the shape and diameter of the valve. But, as this occurs, a tight seal is still preserved-the ball merely seats itself more deeply.

Corrosion-resistant parts

The stainless steel valve and seat of the Armstrong inverted bucket steam trap are individually ground and lapped together in matched sets. All other working parts are wear- and corrosion-resistant stainless steel.

Venting of air and CO2

The Armstrong inverted bucket provides continuous automatic air and CO2 venting with no cooling lag or threat of air binding.

Operation against back pressure

The Armstrong inverted bucket has excellent performance against back pressure. It has no adverse effect on inverted bucket operation other than to reduce its capacity by the low differential. The bucket simply requires less force to pull the valve open and cycle the trap.

Freedom from dirt problems

Armstrong designed its inverted bucket to be virtually free of dirt problems. The valve and seat are at the top of the trap, far away from the larger particles of dirt, which fall to the bottom. Here, the up-and-down action of the bucket pulverizes them.

Since the valve of an inverted bucket is either fully closed or open, dirt particles pass freely. And the swift flow of condensate from under the bucket's edge creates a unique self-scrubbing action that sweeps dirt out of the trap.

Qty:

Part #:501-C5315-2

- Inverted Bucket Steam TrapsEnergy efficient because it's so reliable

The inverted bucket is the most reliable steam trap operating principle known. The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure.

Since the bucket is open at the bottom, it resists damage from water hammer, and wear points are heavily reinforced for long life. The inverted bucket has only two moving parts-the valve lever assembly and the bucket. That means no fixed points, no complicated linkage. Nothing to stick, bind or clog.

Conserves energy even in the presence of wear

Armstrong inverted bucket steam traps open and close based on the difference in density between condensate and steam-the inverted bucket principle. They open and close gently, minimizing wear. This simple fact means that inverted buckets are subject to less wear than some other types of traps.

In fact, as an Armstrong inverted bucket trap wears, its tight seal actually improves. The valve and seat of the Armstrong trap provide essentially line contact-resulting in a tight seal because the entire closing force is concentrated on one narrow seating ring.

An Armstrong inverted bucket steam trap continues to operate efficiently with use. Gradual wear slightly increases the diameter of the seat and alters the shape and diameter of the valve. But, as this occurs, a tight seal is still preserved-the ball merely seats itself more deeply.

Corrosion-resistant parts

The stainless steel valve and seat of the Armstrong inverted bucket steam trap are individually ground and lapped together in matched sets. All other working parts are wear- and corrosion-resistant stainless steel.

Venting of air and CO2

The Armstrong inverted bucket provides continuous automatic air and CO2 venting with no cooling lag or threat of air binding.

Operation against back pressure

The Armstrong inverted bucket has excellent performance against back pressure. It has no adverse effect on inverted bucket operation other than to reduce its capacity by the low differential. The bucket simply requires less force to pull the valve open and cycle the trap.

Freedom from dirt problems

Armstrong designed its inverted bucket to be virtually free of dirt problems. The valve and seat are at the top of the trap, far away from the larger particles of dirt, which fall to the bottom. Here, the up-and-down action of the bucket pulverizes them.

Since the valve of an inverted bucket is either fully closed or open, dirt particles pass freely. And the swift flow of condensate from under the bucket's edge creates a unique self-scrubbing action that sweeps dirt out of the trap.

Qty:

Part #:501-C5318-29

- Inverted Bucket Steam TrapsEnergy efficient because it's so reliable

The inverted bucket is the most reliable steam trap operating principle known. The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure.

Since the bucket is open at the bottom, it resists damage from water hammer, and wear points are heavily reinforced for long life. The inverted bucket has only two moving parts-the valve lever assembly and the bucket. That means no fixed points, no complicated linkage. Nothing to stick, bind or clog.

Conserves energy even in the presence of wear

Armstrong inverted bucket steam traps open and close based on the difference in density between condensate and steam-the inverted bucket principle. They open and close gently, minimizing wear. This simple fact means that inverted buckets are subject to less wear than some other types of traps.

In fact, as an Armstrong inverted bucket trap wears, its tight seal actually improves. The valve and seat of the Armstrong trap provide essentially line contact-resulting in a tight seal because the entire closing force is concentrated on one narrow seating ring.

An Armstrong inverted bucket steam trap continues to operate efficiently with use. Gradual wear slightly increases the diameter of the seat and alters the shape and diameter of the valve. But, as this occurs, a tight seal is still preserved-the ball merely seats itself more deeply.

Corrosion-resistant parts

The stainless steel valve and seat of the Armstrong inverted bucket steam trap are individually ground and lapped together in matched sets. All other working parts are wear- and corrosion-resistant stainless steel.

Venting of air and CO2

The Armstrong inverted bucket provides continuous automatic air and CO2 venting with no cooling lag or threat of air binding.

Operation against back pressure

The Armstrong inverted bucket has excellent performance against back pressure. It has no adverse effect on inverted bucket operation other than to reduce its capacity by the low differential. The bucket simply requires less force to pull the valve open and cycle the trap.

Freedom from dirt problems

Armstrong designed its inverted bucket to be virtually free of dirt problems. The valve and seat are at the top of the trap, far away from the larger particles of dirt, which fall to the bottom. Here, the up-and-down action of the bucket pulverizes them.

Since the valve of an inverted bucket is either fully closed or open, dirt particles pass freely. And the swift flow of condensate from under the bucket's edge creates a unique self-scrubbing action that sweeps dirt out of the trap.

Qty:

Part #:501-C5318-5

- Inverted Bucket Steam TrapsEnergy efficient because it's so reliable

The inverted bucket is the most reliable steam trap operating principle known. The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure.

Since the bucket is open at the bottom, it resists damage from water hammer, and wear points are heavily reinforced for long life. The inverted bucket has only two moving parts-the valve lever assembly and the bucket. That means no fixed points, no complicated linkage. Nothing to stick, bind or clog.

Conserves energy even in the presence of wear

Armstrong inverted bucket steam traps open and close based on the difference in density between condensate and steam-the inverted bucket principle. They open and close gently, minimizing wear. This simple fact means that inverted buckets are subject to less wear than some other types of traps.

In fact, as an Armstrong inverted bucket trap wears, its tight seal actually improves. The valve and seat of the Armstrong trap provide essentially line contact-resulting in a tight seal because the entire closing force is concentrated on one narrow seating ring.

An Armstrong inverted bucket steam trap continues to operate efficiently with use. Gradual wear slightly increases the diameter of the seat and alters the shape and diameter of the valve. But, as this occurs, a tight seal is still preserved-the ball merely seats itself more deeply.

Corrosion-resistant parts

The stainless steel valve and seat of the Armstrong inverted bucket steam trap are individually ground and lapped together in matched sets. All other working parts are wear- and corrosion-resistant stainless steel.

Venting of air and CO2

The Armstrong inverted bucket provides continuous automatic air and CO2 venting with no cooling lag or threat of air binding.

Operation against back pressure

The Armstrong inverted bucket has excellent performance against back pressure. It has no adverse effect on inverted bucket operation other than to reduce its capacity by the low differential. The bucket simply requires less force to pull the valve open and cycle the trap.

Freedom from dirt problems

Armstrong designed its inverted bucket to be virtually free of dirt problems. The valve and seat are at the top of the trap, far away from the larger particles of dirt, which fall to the bottom. Here, the up-and-down action of the bucket pulverizes them.

Since the valve of an inverted bucket is either fully closed or open, dirt particles pass freely. And the swift flow of condensate from under the bucket's edge creates a unique self-scrubbing action that sweeps dirt out of the trap.

Qty:

Part #:501-C5319-3

- Inverted Bucket Steam TrapsEnergy efficient because it's so reliable

The inverted bucket is the most reliable steam trap operating principle known. The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure.

Since the bucket is open at the bottom, it resists damage from water hammer, and wear points are heavily reinforced for long life. The inverted bucket has only two moving parts-the valve lever assembly and the bucket. That means no fixed points, no complicated linkage. Nothing to stick, bind or clog.

Conserves energy even in the presence of wear

Armstrong inverted bucket steam traps open and close based on the difference in density between condensate and steam-the inverted bucket principle. They open and close gently, minimizing wear. This simple fact means that inverted buckets are subject to less wear than some other types of traps.

In fact, as an Armstrong inverted bucket trap wears, its tight seal actually improves. The valve and seat of the Armstrong trap provide essentially line contact-resulting in a tight seal because the entire closing force is concentrated on one narrow seating ring.

An Armstrong inverted bucket steam trap continues to operate efficiently with use. Gradual wear slightly increases the diameter of the seat and alters the shape and diameter of the valve. But, as this occurs, a tight seal is still preserved-the ball merely seats itself more deeply.

Corrosion-resistant parts

The stainless steel valve and seat of the Armstrong inverted bucket steam trap are individually ground and lapped together in matched sets. All other working parts are wear- and corrosion-resistant stainless steel.

Venting of air and CO2

The Armstrong inverted bucket provides continuous automatic air and CO2 venting with no cooling lag or threat of air binding.

Operation against back pressure

The Armstrong inverted bucket has excellent performance against back pressure. It has no adverse effect on inverted bucket operation other than to reduce its capacity by the low differential. The bucket simply requires less force to pull the valve open and cycle the trap.

Freedom from dirt problems

Armstrong designed its inverted bucket to be virtually free of dirt problems. The valve and seat are at the top of the trap, far away from the larger particles of dirt, which fall to the bottom. Here, the up-and-down action of the bucket pulverizes them.

Since the valve of an inverted bucket is either fully closed or open, dirt particles pass freely. And the swift flow of condensate from under the bucket's edge creates a unique self-scrubbing action that sweeps dirt out of the trap.

Qty:

Part #:501-C5319-8

- Inverted Bucket Steam TrapsEnergy efficient because it's so reliable

The inverted bucket is the most reliable steam trap operating principle known. The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure.

Since the bucket is open at the bottom, it resists damage from water hammer, and wear points are heavily reinforced for long life. The inverted bucket has only two moving parts-the valve lever assembly and the bucket. That means no fixed points, no complicated linkage. Nothing to stick, bind or clog.

Conserves energy even in the presence of wear

Armstrong inverted bucket steam traps open and close based on the difference in density between condensate and steam-the inverted bucket principle. They open and close gently, minimizing wear. This simple fact means that inverted buckets are subject to less wear than some other types of traps.

In fact, as an Armstrong inverted bucket trap wears, its tight seal actually improves. The valve and seat of the Armstrong trap provide essentially line contact-resulting in a tight seal because the entire closing force is concentrated on one narrow seating ring.

An Armstrong inverted bucket steam trap continues to operate efficiently with use. Gradual wear slightly increases the diameter of the seat and alters the shape and diameter of the valve. But, as this occurs, a tight seal is still preserved-the ball merely seats itself more deeply.

Corrosion-resistant parts

The stainless steel valve and seat of the Armstrong inverted bucket steam trap are individually ground and lapped together in matched sets. All other working parts are wear- and corrosion-resistant stainless steel.

Venting of air and CO2

The Armstrong inverted bucket provides continuous automatic air and CO2 venting with no cooling lag or threat of air binding.

Operation against back pressure

The Armstrong inverted bucket has excellent performance against back pressure. It has no adverse effect on inverted bucket operation other than to reduce its capacity by the low differential. The bucket simply requires less force to pull the valve open and cycle the trap.

Freedom from dirt problems

Armstrong designed its inverted bucket to be virtually free of dirt problems. The valve and seat are at the top of the trap, far away from the larger particles of dirt, which fall to the bottom. Here, the up-and-down action of the bucket pulverizes them.

Since the valve of an inverted bucket is either fully closed or open, dirt particles pass freely. And the swift flow of condensate from under the bucket's edge creates a unique self-scrubbing action that sweeps dirt out of the trap.

Qty:

Armstrong 1810 1/2in NPT #38 Orifice 200lb Stainless Steel, Inverted Bucket Trap, Horizontal C5323-1

- Inverted Bucket Steam TrapsEnergy efficient because it's so reliable

The inverted bucket is the most reliable steam trap operating principle known. The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure.

Since the bucket is open at the bottom, it resists damage from water hammer, and wear points are heavily reinforced for long life. The inverted bucket has only two moving parts-the valve lever assembly and the bucket. That means no fixed points, no complicated linkage. Nothing to stick, bind or clog.

Conserves energy even in the presence of wear

Armstrong inverted bucket steam traps open and close based on the difference in density between condensate and steam-the inverted bucket principle. They open and close gently, minimizing wear. This simple fact means that inverted buckets are subject to less wear than some other types of traps.

In fact, as an Armstrong inverted bucket trap wears, its tight seal actually improves. The valve and seat of the Armstrong trap provide essentially line contact-resulting in a tight seal because the entire closing force is concentrated on one narrow seating ring.

An Armstrong inverted bucket steam trap continues to operate efficiently with use. Gradual wear slightly increases the diameter of the seat and alters the shape and diameter of the valve. But, as this occurs, a tight seal is still preserved-the ball merely seats itself more deeply.

Corrosion-resistant parts

The stainless steel valve and seat of the Armstrong inverted bucket steam trap are individually ground and lapped together in matched sets. All other working parts are wear- and corrosion-resistant stainless steel.

Venting of air and CO2

The Armstrong inverted bucket provides continuous automatic air and CO2 venting with no cooling lag or threat of air binding.

Operation against back pressure

The Armstrong inverted bucket has excellent performance against back pressure. It has no adverse effect on inverted bucket operation other than to reduce its capacity by the low differential. The bucket simply requires less force to pull the valve open and cycle the trap.

Freedom from dirt problems

Armstrong designed its inverted bucket to be virtually free of dirt problems. The valve and seat are at the top of the trap, far away from the larger particles of dirt, which fall to the bottom. Here, the up-and-down action of the bucket pulverizes them.

Since the valve of an inverted bucket is either fully closed or open, dirt particles pass freely. And the swift flow of condensate from under the bucket's edge creates a unique self-scrubbing action that sweeps dirt out of the trap.

Qty:

Part #:501-C5323-10

- Inverted Bucket Steam TrapsEnergy efficient because it's so reliable

The inverted bucket is the most reliable steam trap operating principle known. The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure.

Since the bucket is open at the bottom, it resists damage from water hammer, and wear points are heavily reinforced for long life. The inverted bucket has only two moving parts-the valve lever assembly and the bucket. That means no fixed points, no complicated linkage. Nothing to stick, bind or clog.

Conserves energy even in the presence of wear

Armstrong inverted bucket steam traps open and close based on the difference in density between condensate and steam-the inverted bucket principle. They open and close gently, minimizing wear. This simple fact means that inverted buckets are subject to less wear than some other types of traps.

In fact, as an Armstrong inverted bucket trap wears, its tight seal actually improves. The valve and seat of the Armstrong trap provide essentially line contact-resulting in a tight seal because the entire closing force is concentrated on one narrow seating ring.

An Armstrong inverted bucket steam trap continues to operate efficiently with use. Gradual wear slightly increases the diameter of the seat and alters the shape and diameter of the valve. But, as this occurs, a tight seal is still preserved-the ball merely seats itself more deeply.

Corrosion-resistant parts

The stainless steel valve and seat of the Armstrong inverted bucket steam trap are individually ground and lapped together in matched sets. All other working parts are wear- and corrosion-resistant stainless steel.

Venting of air and CO2

The Armstrong inverted bucket provides continuous automatic air and CO2 venting with no cooling lag or threat of air binding.

Operation against back pressure

The Armstrong inverted bucket has excellent performance against back pressure. It has no adverse effect on inverted bucket operation other than to reduce its capacity by the low differential. The bucket simply requires less force to pull the valve open and cycle the trap.

Freedom from dirt problems

Armstrong designed its inverted bucket to be virtually free of dirt problems. The valve and seat are at the top of the trap, far away from the larger particles of dirt, which fall to the bottom. Here, the up-and-down action of the bucket pulverizes them.

Since the valve of an inverted bucket is either fully closed or open, dirt particles pass freely. And the swift flow of condensate from under the bucket's edge creates a unique self-scrubbing action that sweeps dirt out of the trap.

Qty:

Part #:501-C5323-13

- Inverted Bucket Steam TrapsEnergy efficient because it's so reliable

The inverted bucket is the most reliable steam trap operating principle known. The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure.

Since the bucket is open at the bottom, it resists damage from water hammer, and wear points are heavily reinforced for long life. The inverted bucket has only two moving parts-the valve lever assembly and the bucket. That means no fixed points, no complicated linkage. Nothing to stick, bind or clog.

Conserves energy even in the presence of wear

Armstrong inverted bucket steam traps open and close based on the difference in density between condensate and steam-the inverted bucket principle. They open and close gently, minimizing wear. This simple fact means that inverted buckets are subject to less wear than some other types of traps.

In fact, as an Armstrong inverted bucket trap wears, its tight seal actually improves. The valve and seat of the Armstrong trap provide essentially line contact-resulting in a tight seal because the entire closing force is concentrated on one narrow seating ring.

An Armstrong inverted bucket steam trap continues to operate efficiently with use. Gradual wear slightly increases the diameter of the seat and alters the shape and diameter of the valve. But, as this occurs, a tight seal is still preserved-the ball merely seats itself more deeply.

Corrosion-resistant parts

The stainless steel valve and seat of the Armstrong inverted bucket steam trap are individually ground and lapped together in matched sets. All other working parts are wear- and corrosion-resistant stainless steel.

Venting of air and CO2

The Armstrong inverted bucket provides continuous automatic air and CO2 venting with no cooling lag or threat of air binding.

Operation against back pressure

The Armstrong inverted bucket has excellent performance against back pressure. It has no adverse effect on inverted bucket operation other than to reduce its capacity by the low differential. The bucket simply requires less force to pull the valve open and cycle the trap.

Freedom from dirt problems

Armstrong designed its inverted bucket to be virtually free of dirt problems. The valve and seat are at the top of the trap, far away from the larger particles of dirt, which fall to the bottom. Here, the up-and-down action of the bucket pulverizes them.

Since the valve of an inverted bucket is either fully closed or open, dirt particles pass freely. And the swift flow of condensate from under the bucket's edge creates a unique self-scrubbing action that sweeps dirt out of the trap.

Qty:

Part #:501-C5323-4

- Inverted Bucket Steam TrapsEnergy efficient because it's so reliable

The inverted bucket is the most reliable steam trap operating principle known. The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure.

Since the bucket is open at the bottom, it resists damage from water hammer, and wear points are heavily reinforced for long life. The inverted bucket has only two moving parts-the valve lever assembly and the bucket. That means no fixed points, no complicated linkage. Nothing to stick, bind or clog.

Conserves energy even in the presence of wear

Armstrong inverted bucket steam traps open and close based on the difference in density between condensate and steam-the inverted bucket principle. They open and close gently, minimizing wear. This simple fact means that inverted buckets are subject to less wear than some other types of traps.

In fact, as an Armstrong inverted bucket trap wears, its tight seal actually improves. The valve and seat of the Armstrong trap provide essentially line contact-resulting in a tight seal because the entire closing force is concentrated on one narrow seating ring.

An Armstrong inverted bucket steam trap continues to operate efficiently with use. Gradual wear slightly increases the diameter of the seat and alters the shape and diameter of the valve. But, as this occurs, a tight seal is still preserved-the ball merely seats itself more deeply.

Corrosion-resistant parts

The stainless steel valve and seat of the Armstrong inverted bucket steam trap are individually ground and lapped together in matched sets. All other working parts are wear- and corrosion-resistant stainless steel.

Venting of air and CO2

The Armstrong inverted bucket provides continuous automatic air and CO2 venting with no cooling lag or threat of air binding.

Operation against back pressure

The Armstrong inverted bucket has excellent performance against back pressure. It has no adverse effect on inverted bucket operation other than to reduce its capacity by the low differential. The bucket simply requires less force to pull the valve open and cycle the trap.

Freedom from dirt problems

Armstrong designed its inverted bucket to be virtually free of dirt problems. The valve and seat are at the top of the trap, far away from the larger particles of dirt, which fall to the bottom. Here, the up-and-down action of the bucket pulverizes them.

Since the valve of an inverted bucket is either fully closed or open, dirt particles pass freely. And the swift flow of condensate from under the bucket's edge creates a unique self-scrubbing action that sweeps dirt out of the trap.

Qty:

Displaying: 1 - 24 of 73 Matching Items